diff --git a/README.md b/README.md

index e1ae2980..b9042658 100644

--- a/README.md

+++ b/README.md

@@ -16,67 +16,24 @@ Therefore this is an attempt to:

- ***NEW*** 📢: *Medium-power* BLDC driver (<30Amps): [Arduino SimpleFOCPowerShield ](https://github.com/simplefoc/Arduino-SimpleFOC-PowerShield).

- See also [@byDagor](https://github.com/byDagor)'s *fully-integrated* ESP32 based board: [Dagor Brushless Controller](https://github.com/byDagor/Dagor-Brushless-Controller)

-##### NEW RELEASE 📢: SimpleFOClibrary v2.1

-> - **Initial current sensing support**🎉

-> - Inline current sensors

-> - adaptive zero finding and shunt direction

-> - **Implemented real torque control**

-> - using voltage

-> - using current magnitude (one current)

-> - using FOC currents ( d-q currents ) - real foc control

-> - SVPWM full implementation d+q axis

-> - **Simplified sensor implementation**📢

-> - For new sensor implementation only one function necessary `getAngle()`

-> - Upgrade of the HallSensor implementation by [@owennewo](https://github.com/owennewo)

-> - Support for Arduino DUE - everything except the 6PWM mode

-> - Support for ATMega328pb

-> - bugfix for the Teensy boards ( setting 3pwm )

-> - extended support for 2PWM stepper drivers - by [@zjor](https://github.com/zjor)

-> - included F macro for shrinking string memory usage - moved to programming memory

-> - disable phase support for 3pwm driver

-> - not yet for 6pwm

-> - rewritten `initFOC()`

-> - can be skipped and outputs much more info

-> - align sensor: direction + zero offset + pole pair check

-> - align current sense

-> - sensor offset supported (`motor.sensor_offset`)

-> - **refactored motor commands interface**

-> - much more flexible and easy to extend

-> - very easy to add new commands and function callbacks

-> - implemented motor+pid+lpf commands of-the-shelf

-> - Added **step/dir interface**

-> - integrated as an optional communication channel

->

-> BEWARE 📢 slight API changes included

-> - `ControlType` renamed into `MotionControlType`

-> - `ControlType::voltage` does not exist any more now - `MotionControlType::torque`

-

-

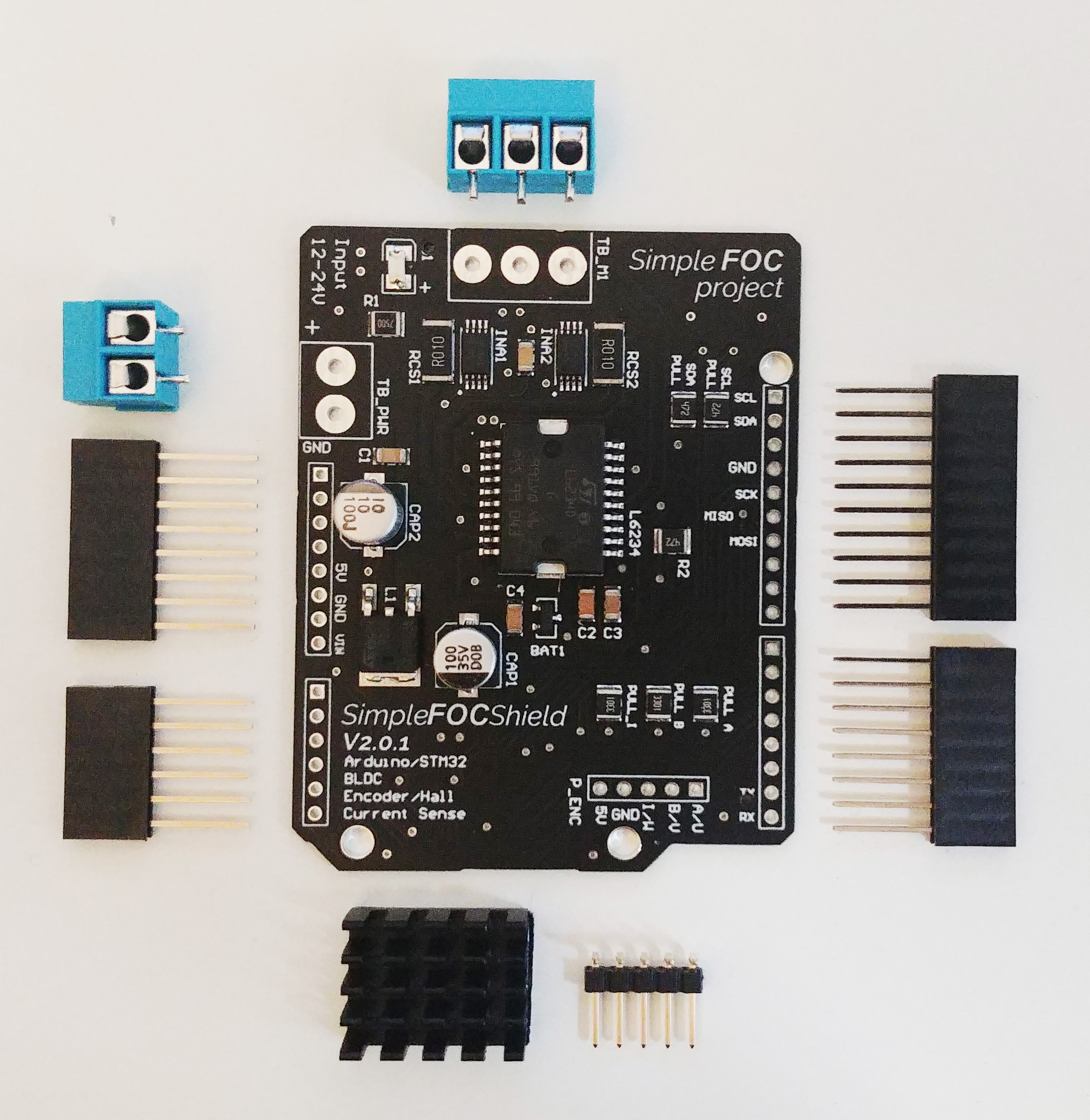

-## Arduino *SimpleFOCShield* v2.0.3

-

-

- -

-

-

-

-

-### Features

-- **Plug & play**: In combination with Arduino *Simple**FOC**library* - [github](https://github.com/simplefoc/Arduino-FOC)

-- **Low-cost**: Price of €15 - [Check the pricing](https://www.simplefoc.com/shop)

-- **In-line current sensing**: Up to 3Amps/5Amps bidirectional

- - configurable: 3.3Amps - 3.3V adc, 5Amps - 5V adc

-- **Integrated 8V regulator**:

- - Enable/disable by soldering pads

-- **Max power 120W** - max current 5A, power-supply 12-24V

- - Designed for Gimbal motors with the internal resistance >10 Ωs.

-- **Stackable**: running 2 motors in the same time

-- **Encoder/Hall sensors interface**: Integrated 3.3kΩ pullups (configurable)

-- **I2C interface**: Integrated 4.7kΩ pullups (configurable)

-- **Configurable pinout**: Hardware configuration - soldering connections

-- **Arduino headers**: Arduino UNO, Arduino MEGA, STM32 Nucleo boards...

-- **Open Source**: Fully available fabrication files - [how to make it yourself](https://docs.simplefoc.com/arduino_simplefoc_shield_fabrication)

-

-

-

+##### Release notes be: SimpleFOClibrary v2.1.1

+> - bugfixes commander

+> - bugfix `voltage_limit` when provided `phase_resistance`

+> - bugfix `hall_sensor` examples

+> - added examples fot the PowerShield

+> - added initial support for `MagneticSensorPWM`

+> - SAMD51 support

+> - **initial support for Raspberry pi Pico**

+> - added examples to find the raw max and min of the analog and pwm sensor

+> - extension of the `Commander` interface

+> - added pwm centering option `WC`

+> - added pwm modulation cmd `WT`

+> - improved esp32 implementation to avoid the need for mcpwm.h changes by @tschundler

+> - issue #62: motor.shaft_angle setting in the motor.initFOC()

+> - issue #76: esp32 division by zero

+> - issue #46: commander end of line character - by @maxlem

+> - [community fix](https://community.simplefoc.com/t/as5600-dead-spot-around-0/208) AS5600 register value

+> - renamed `Pullup::EXTERN` and `Pullup::INTERN` to `Pullup::USE_EXTERN` and `Pullup::USE_INTERN`

## Arduino *SimpleFOClibrary* v2.1

@@ -108,6 +65,33 @@ This video demonstrates the *Simple**FOC**library* basic usage, electronic conne

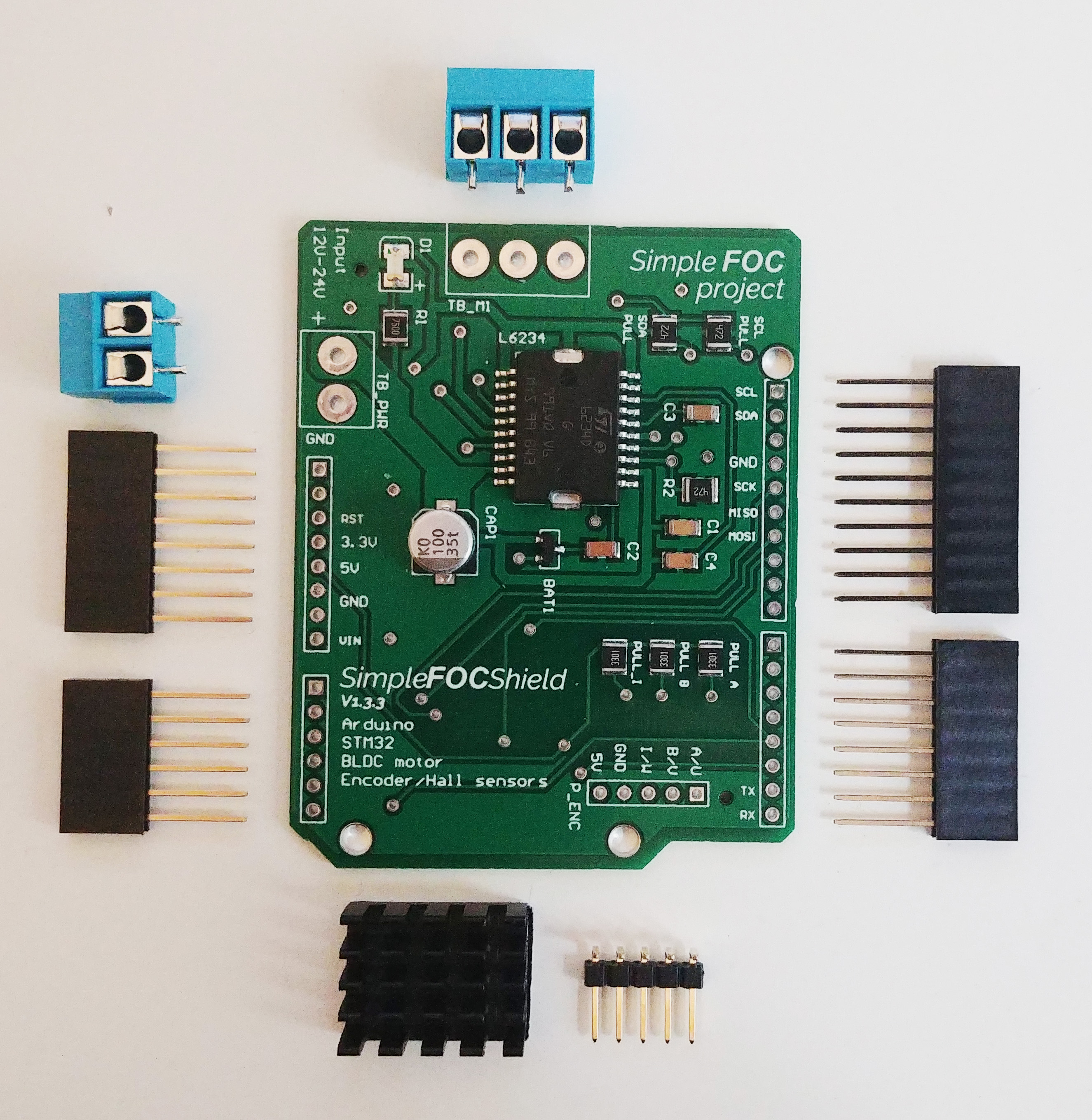

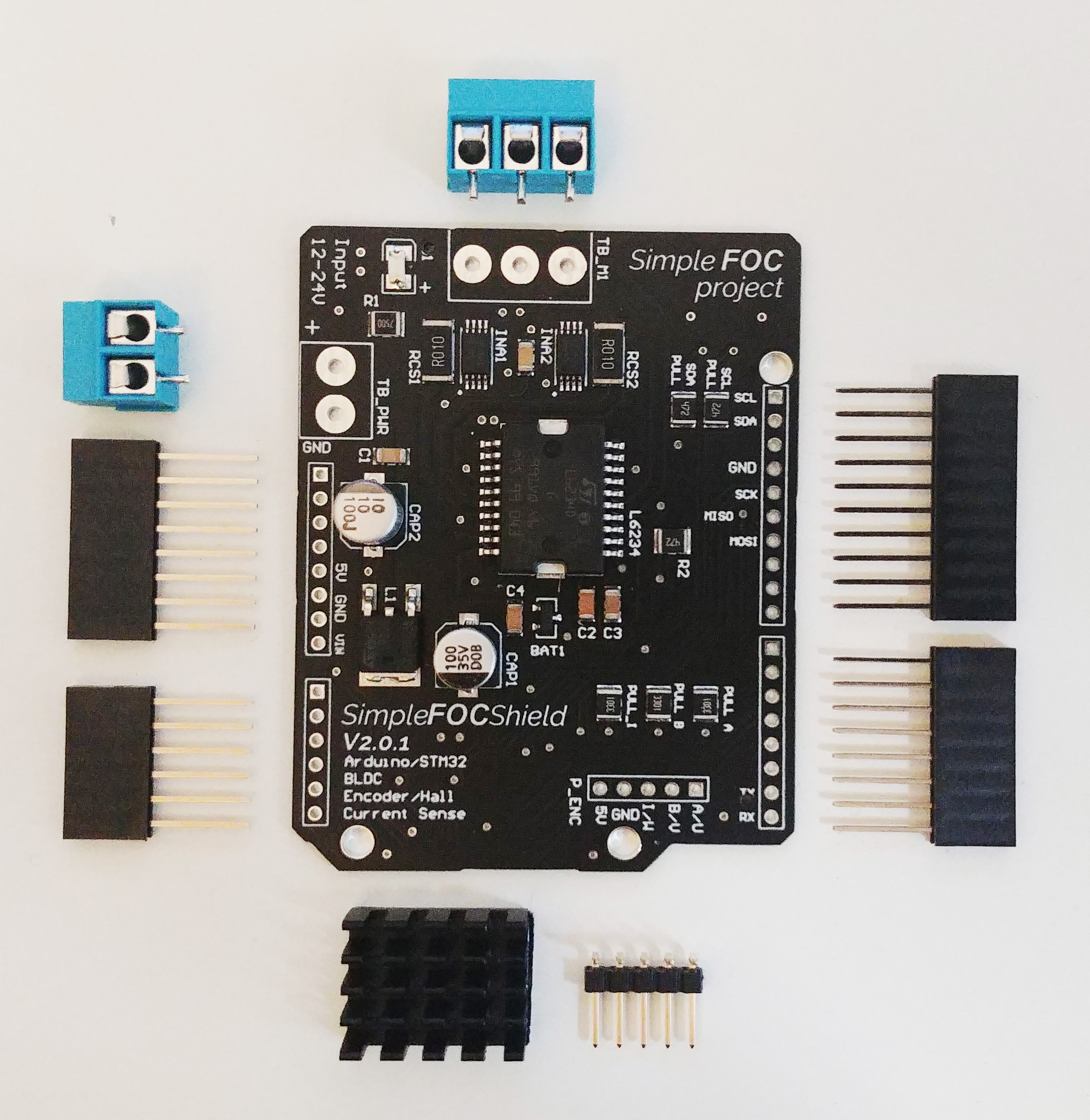

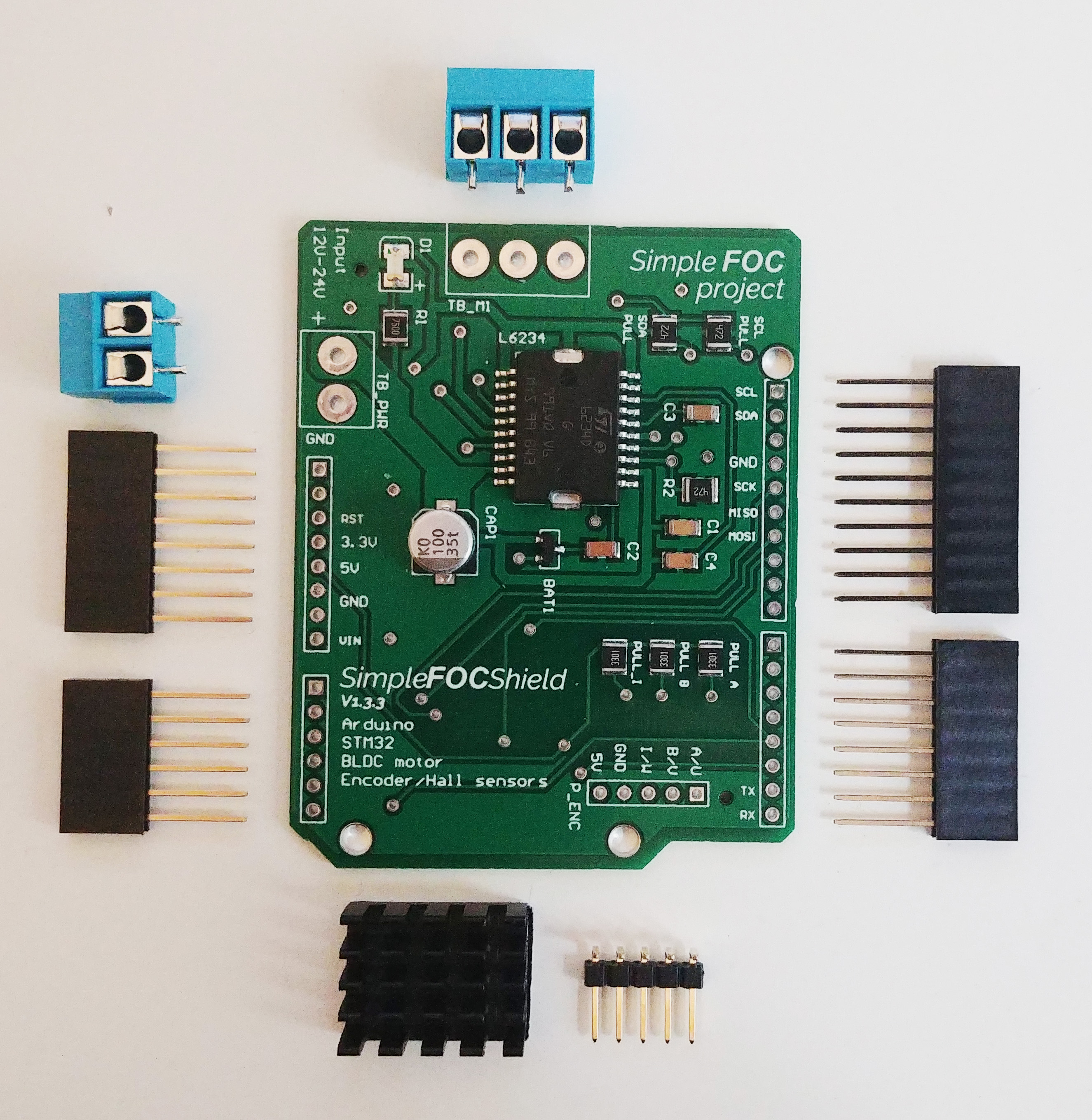

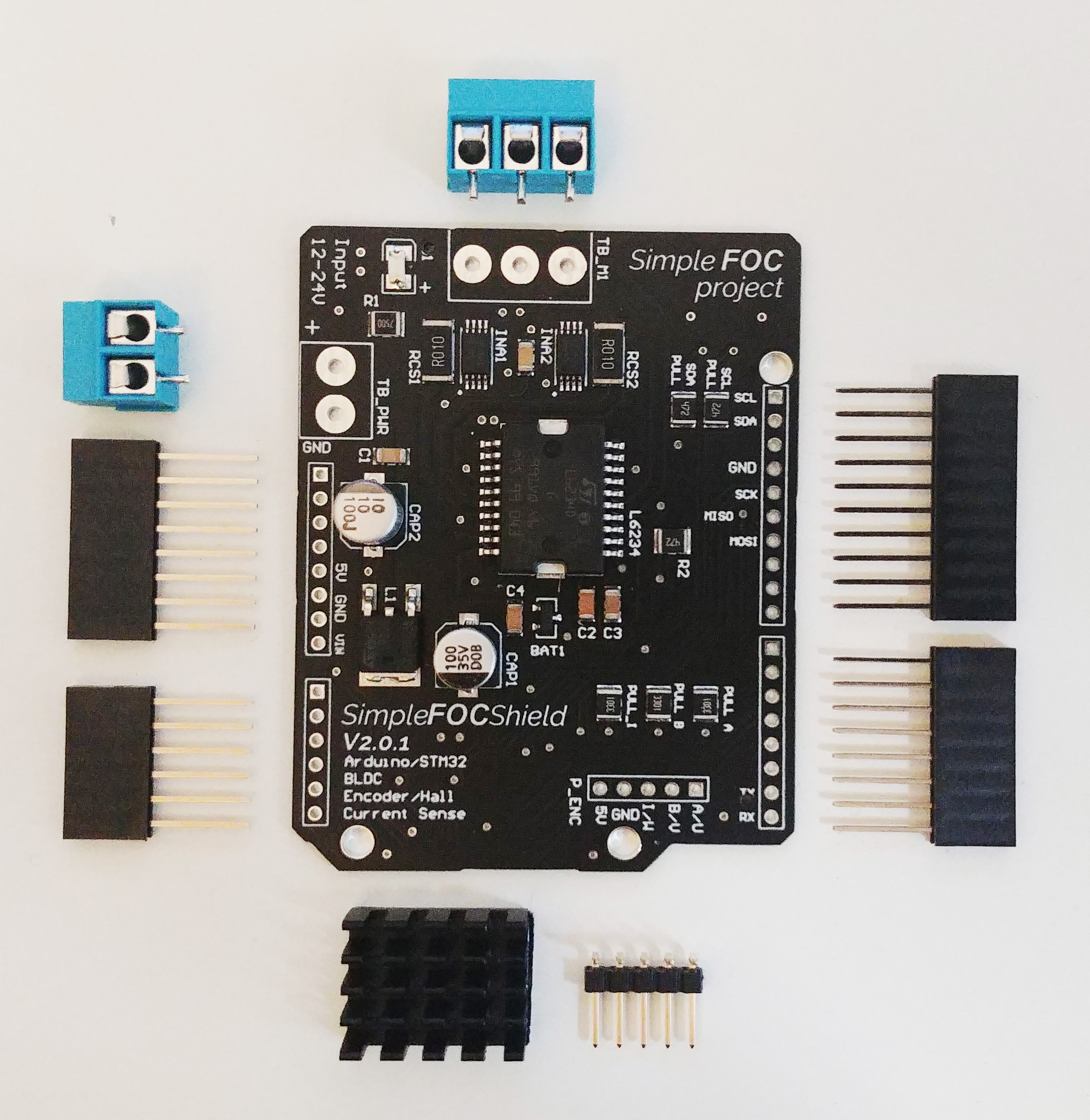

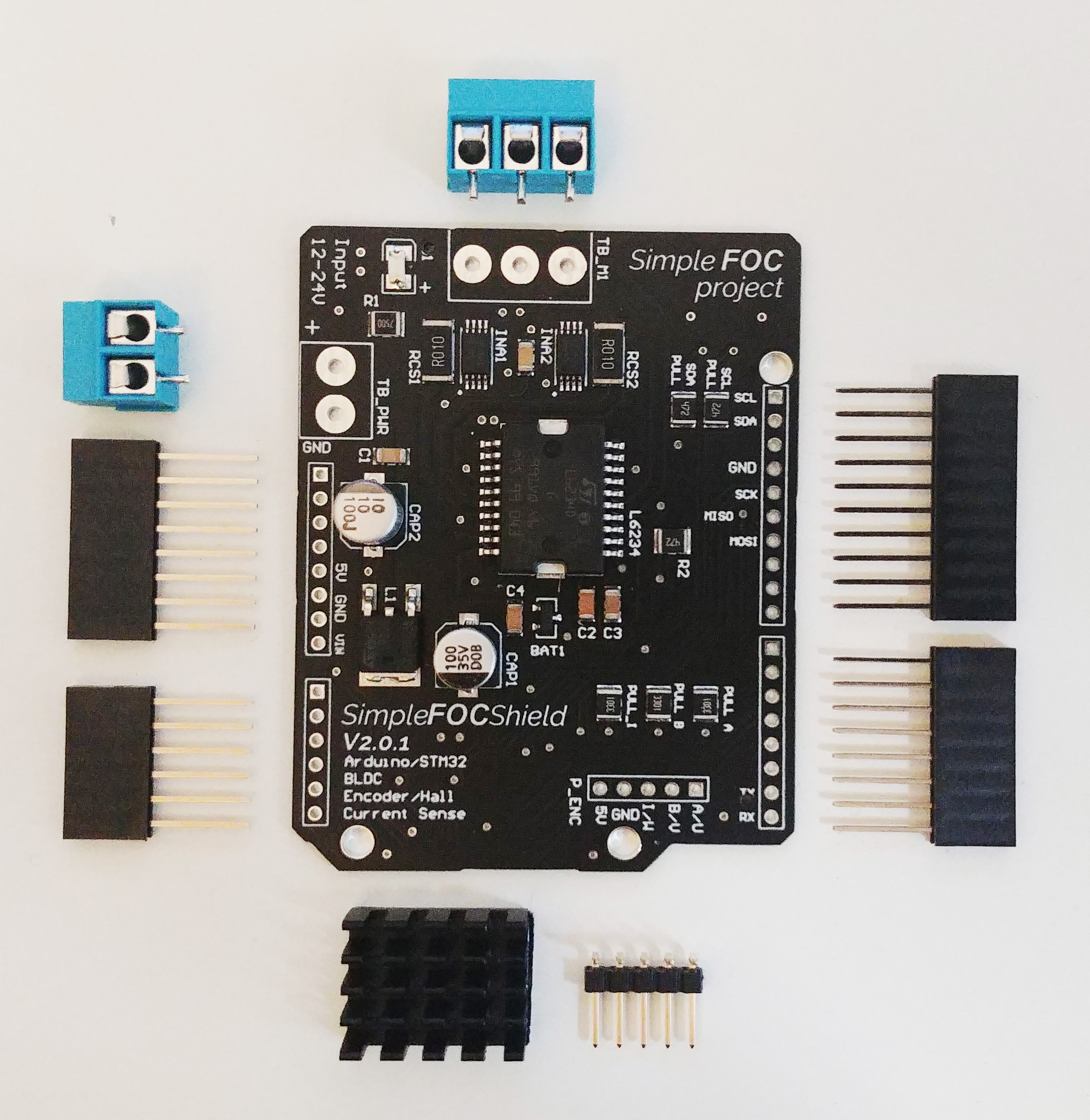

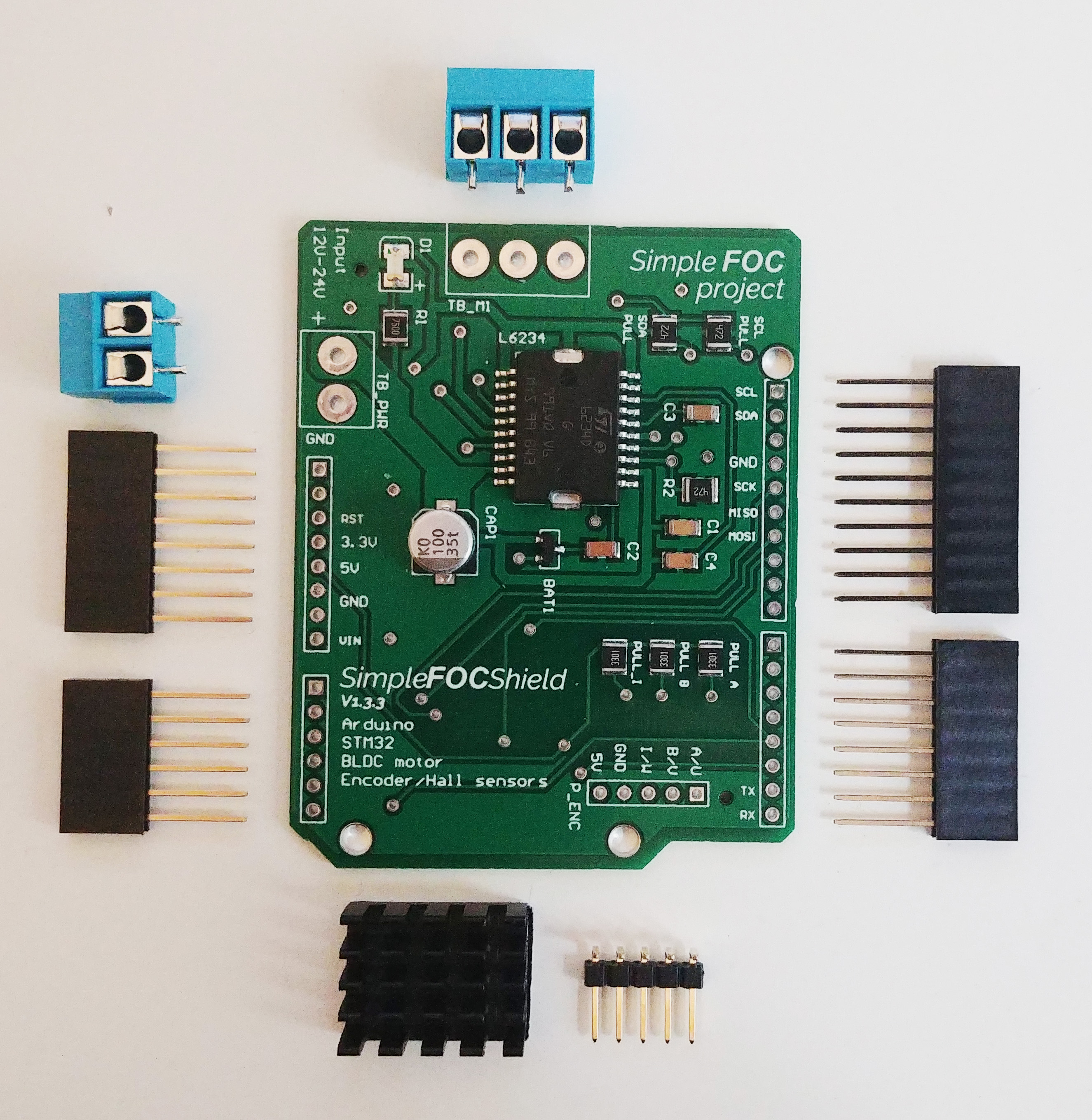

+## Arduino *SimpleFOCShield* v2.0.3

+

+

+ +

+

+

+

+

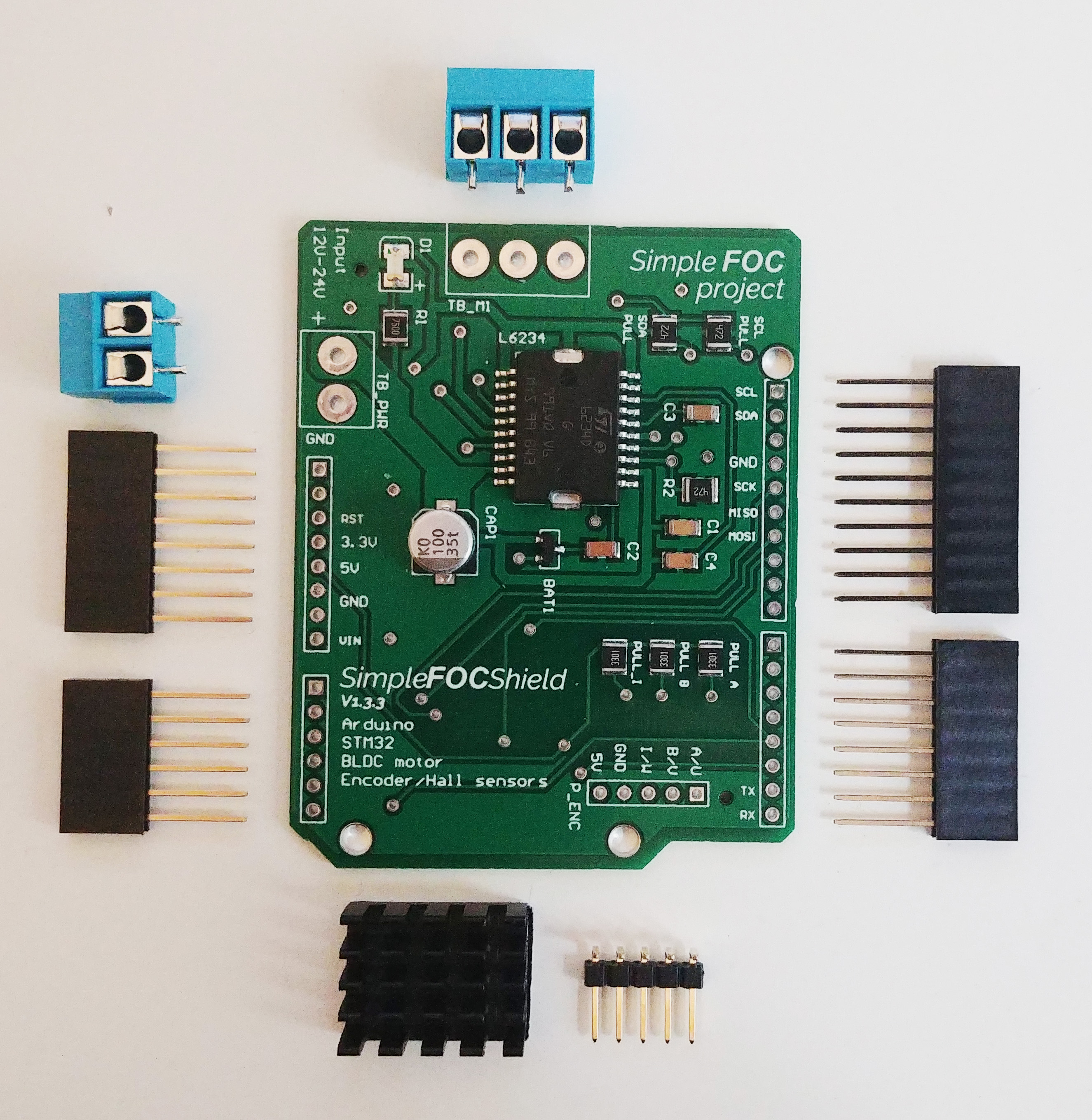

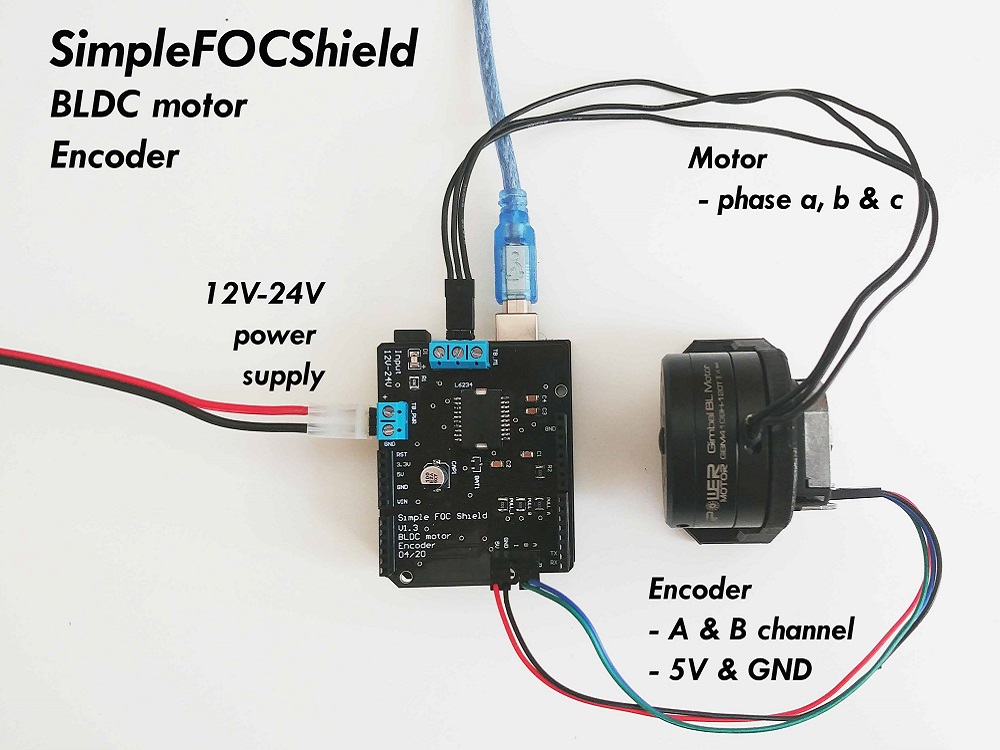

+### Features

+- **Plug & play**: In combination with Arduino *Simple**FOC**library* - [github](https://github.com/simplefoc/Arduino-FOC)

+- **Low-cost**: Price of €15 - [Check the pricing](https://www.simplefoc.com/shop)

+- **In-line current sensing**: Up to 3Amps/5Amps bidirectional

+ - configurable: 3.3Amps - 3.3V adc, 5Amps - 5V adc

+- **Integrated 8V regulator**:

+ - Enable/disable by soldering pads

+- **Max power 120W** - max current 5A, power-supply 12-24V

+ - Designed for Gimbal motors with the internal resistance >10 Ωs.

+- **Stackable**: running 2 motors in the same time

+- **Encoder/Hall sensors interface**: Integrated 3.3kΩ pullups (configurable)

+- **I2C interface**: Integrated 4.7kΩ pullups (configurable)

+- **Configurable pinout**: Hardware configuration - soldering connections

+- **Arduino headers**: Arduino UNO, Arduino MEGA, STM32 Nucleo boards...

+- **Open Source**: Fully available fabrication files - [how to make it yourself](https://docs.simplefoc.com/arduino_simplefoc_shield_fabrication)

+

+

+

+

+

## Getting Started

Depending on if you want to use this library as the plug and play Arduino library or you want to get insight in the algorithm and make changes there are two ways to install this code.

diff --git a/examples/hardware_specific_examples/Bluepill_examples/magnetic_sensor/bluepill_position_control/bluepill_position_control.ino b/examples/hardware_specific_examples/Bluepill_examples/magnetic_sensor/bluepill_position_control/bluepill_position_control.ino

index 54608e8a..0adf4c17 100644

--- a/examples/hardware_specific_examples/Bluepill_examples/magnetic_sensor/bluepill_position_control/bluepill_position_control.ino

+++ b/examples/hardware_specific_examples/Bluepill_examples/magnetic_sensor/bluepill_position_control/bluepill_position_control.ino

@@ -17,7 +17,7 @@ MagneticSensorSPI sensor = MagneticSensorSPI(PA4, 14, 0x3FFF);

// make sure to use the pull-ups!!

// SDA PB7

// SCL PB6

-//MagneticSensorI2C sensor = MagneticSensorI2C(0x36, 12, 0x0E, 4);

+//MagneticSensorI2C sensor = MagneticSensorI2C(0x36, 12, 0X0C, 4);

// Motor instance

BLDCMotor motor = BLDCMotor(11);

diff --git a/examples/hardware_specific_examples/SimpleFOCShield/version_v2/double_full_control_example/double_full_control_example.ino b/examples/hardware_specific_examples/SimpleFOCShield/version_v2/double_full_control_example/double_full_control_example.ino

index 17b98ce5..757ae0f1 100644

--- a/examples/hardware_specific_examples/SimpleFOCShield/version_v2/double_full_control_example/double_full_control_example.ino

+++ b/examples/hardware_specific_examples/SimpleFOCShield/version_v2/double_full_control_example/double_full_control_example.ino

@@ -23,9 +23,11 @@ void doB2(){encoder2.handleB();}

// inline current sensor instance

+// check if your board has R010 (0.01 ohm resistor) or R006 (0.006 mOhm resistor)

InlineCurrentSense current_sense1 = InlineCurrentSense(0.01, 50.0, A0, A2);

// inline current sensor instance

+// check if your board has R010 (0.01 ohm resistor) or R006 (0.006 mOhm resistor)

InlineCurrentSense current_sense2 = InlineCurrentSense(0.01, 50.0, A1, A3);

// commander communication instance

diff --git a/examples/hardware_specific_examples/SimpleFOCShield/version_v2/single_full_control_example/single_full_control_example.ino b/examples/hardware_specific_examples/SimpleFOCShield/version_v2/single_full_control_example/single_full_control_example.ino

index 70444520..c0f6a10b 100644

--- a/examples/hardware_specific_examples/SimpleFOCShield/version_v2/single_full_control_example/single_full_control_example.ino

+++ b/examples/hardware_specific_examples/SimpleFOCShield/version_v2/single_full_control_example/single_full_control_example.ino

@@ -12,6 +12,7 @@ void doA(){encoder.handleA();}

void doB(){encoder.handleB();}

// inline current sensor instance

+// check if your board has R010 (0.01 ohm resistor) or R006 (0.006 mOhm resistor)

InlineCurrentSense current_sense = InlineCurrentSense(0.01, 50.0, A0, A2);

// commander communication instance

diff --git a/examples/utils/calibration/alignment_and_cogging_test/alignment_and_cogging_test.ino b/examples/utils/calibration/alignment_and_cogging_test/alignment_and_cogging_test.ino

index 8292ecf4..708e2d9e 100644

--- a/examples/utils/calibration/alignment_and_cogging_test/alignment_and_cogging_test.ino

+++ b/examples/utils/calibration/alignment_and_cogging_test/alignment_and_cogging_test.ino

@@ -5,7 +5,7 @@ BLDCMotor motor = BLDCMotor(11);

BLDCDriver3PWM driver = BLDCDriver3PWM(9, 10, 11, 8);

//StepperMotor motor = StepperMotor(50);

//StepperDriver4PWM driver = StepperDriver4PWM(9, 5, 10, 6, 8);

-MagneticSensorI2C sensor = MagneticSensorI2C(0x36, 12, 0x0E, 4);

+MagneticSensorI2C sensor = MagneticSensorI2C(0x36, 12, 0X0C, 4);

/**

diff --git a/examples/utils/calibration/find_pole_pair_number/magnetic_sensor/find_pole_pairs_number/find_pole_pairs_number.ino b/examples/utils/calibration/find_pole_pair_number/magnetic_sensor/find_pole_pairs_number/find_pole_pairs_number.ino

index 4f6e83cc..cc4bd4d0 100644

--- a/examples/utils/calibration/find_pole_pair_number/magnetic_sensor/find_pole_pairs_number/find_pole_pairs_number.ino

+++ b/examples/utils/calibration/find_pole_pair_number/magnetic_sensor/find_pole_pairs_number/find_pole_pairs_number.ino

@@ -27,7 +27,7 @@ BLDCDriver3PWM driver = BLDCDriver3PWM(9, 5, 6, 8);

// magnetic sensor instance - SPI

MagneticSensorSPI sensor = MagneticSensorSPI(10, 14, 0x3FFF);

// magnetic sensor instance - I2C

-//MagneticSensorI2C sensor = MagneticSensorI2C(0x36, 12, 0x0E, 4);

+//MagneticSensorI2C sensor = MagneticSensorI2C(0x36, 12, 0X0C, 4);

// magnetic sensor instance - analog output

// MagneticSensorAnalog sensor = MagneticSensorAnalog(A1, 14, 1020);

diff --git a/examples/utils/calibration/find_sensor_offset_and_direction/find_sensor_offset_and_direction.ino b/examples/utils/calibration/find_sensor_offset_and_direction/find_sensor_offset_and_direction.ino

index a54fcea4..3ad87cca 100644

--- a/examples/utils/calibration/find_sensor_offset_and_direction/find_sensor_offset_and_direction.ino

+++ b/examples/utils/calibration/find_sensor_offset_and_direction/find_sensor_offset_and_direction.ino

@@ -15,7 +15,7 @@

// magnetic sensor instance - SPI

//MagneticSensorSPI sensor = MagneticSensorSPI(10, 14, 0x3FFF);

// magnetic sensor instance - I2C

-//MagneticSensorI2C sensor = MagneticSensorI2C(0x36, 12, 0x0E, 4);

+//MagneticSensorI2C sensor = MagneticSensorI2C(0x36, 12, 0X0C, 4);

// magnetic sensor instance - analog output

MagneticSensorAnalog sensor = MagneticSensorAnalog(A1, 14, 1020);

diff --git a/examples/utils/sensor_test/encoder/encoder_example/encoder_example.ino b/examples/utils/sensor_test/encoder/encoder_example/encoder_example.ino

index 0fa87522..66aca6d8 100644

--- a/examples/utils/sensor_test/encoder/encoder_example/encoder_example.ino

+++ b/examples/utils/sensor_test/encoder/encoder_example/encoder_example.ino

@@ -21,7 +21,7 @@ void setup() {

encoder.quadrature = Quadrature::ON;

// check if you need internal pullups

- encoder.pullup = Pullup::EXTERN;

+ encoder.pullup = Pullup::USE_EXTERN;

// initialise encoder hardware

encoder.init();

diff --git a/examples/utils/sensor_test/encoder/encoder_software_interrupts_example/encoder_software_interrupts_example.ino b/examples/utils/sensor_test/encoder/encoder_software_interrupts_example/encoder_software_interrupts_example.ino

index 7c38bb59..a979d9a0 100644

--- a/examples/utils/sensor_test/encoder/encoder_software_interrupts_example/encoder_software_interrupts_example.ino

+++ b/examples/utils/sensor_test/encoder/encoder_software_interrupts_example/encoder_software_interrupts_example.ino

@@ -32,7 +32,7 @@ void setup() {

encoder.quadrature = Quadrature::ON;

// check if you need internal pullups

- encoder.pullup = Pullup::EXTERN;

+ encoder.pullup = Pullup::USE_EXTERN;

// initialise encoder hardware

encoder.init();

diff --git a/examples/utils/sensor_test/hall_sensors/hall_sensor_example/hall_sensor_example.ino b/examples/utils/sensor_test/hall_sensors/hall_sensor_example/hall_sensor_example.ino

index 965aec7a..6c19a2e9 100644

--- a/examples/utils/sensor_test/hall_sensors/hall_sensor_example/hall_sensor_example.ino

+++ b/examples/utils/sensor_test/hall_sensors/hall_sensor_example/hall_sensor_example.ino

@@ -25,7 +25,7 @@ void setup() {

Serial.begin(115200);

// check if you need internal pullups

- sensor.pullup = Pullup::EXTERN;

+ sensor.pullup = Pullup::USE_EXTERN;

// initialise encoder hardware

sensor.init();

diff --git a/examples/utils/sensor_test/hall_sensors/hall_sensor_software_interrupts_example/hall_sensors_software_interrupt_example.ino b/examples/utils/sensor_test/hall_sensors/hall_sensor_software_interrupts_example/hall_sensors_software_interrupt_example.ino

index cac8dc00..523af03f 100644

--- a/examples/utils/sensor_test/hall_sensors/hall_sensor_software_interrupts_example/hall_sensors_software_interrupt_example.ino

+++ b/examples/utils/sensor_test/hall_sensors/hall_sensor_software_interrupts_example/hall_sensors_software_interrupt_example.ino

@@ -34,7 +34,7 @@ void setup() {

Serial.begin(115200);

// check if you need internal pullups

- sensor.pullup = Pullup::EXTERN;

+ sensor.pullup = Pullup::USE_EXTERN;

// initialise encoder hardware

sensor.init();

diff --git a/examples/utils/sensor_test/magnetic_sensors/magnetic_sensor_analog_example/find_raw_min_max/find_raw_min_max.ino b/examples/utils/sensor_test/magnetic_sensors/magnetic_sensor_analog_example/find_raw_min_max/find_raw_min_max.ino

new file mode 100644

index 00000000..e45b0278

--- /dev/null

+++ b/examples/utils/sensor_test/magnetic_sensors/magnetic_sensor_analog_example/find_raw_min_max/find_raw_min_max.ino

@@ -0,0 +1,51 @@

+#include

+

+/**

+ * An example to find out the raw max and min count to be provided to the constructor

+ * Spin your motor/sensor/magnet to see what is the maximum output of the sensor and what is the minimum value

+ * And replace values 14 and 1020 with new values. Once when you replace them make sure there is no jump in the angle reading sensor.getAngle().

+ * If there is a jump that means you can still find better values.

+ */

+

+/**

+ * Magnetic sensor reading analog voltage on pin A1. This voltage is proportional to rotation position.

+ * Tested on AS5600 magnetic sensor running in 'analog mode'. Note AS5600 works better in 'i2C mode' (less noise) but only supports one sensor per i2c bus.

+ *

+ * MagneticSensorAnalog(uint8_t _pinAnalog, int _min, int _max)

+ * - pinAnalog - the pin that is reading the pwm from magnetic sensor

+ * - min_raw_count - the smallest expected reading. Whilst you might expect it to be 0 it is often ~15. Getting this wrong results in a small click once per revolution

+ * - max_raw_count - the largest value read. whilst you might expect it to be 2^10 = 1023 it is often ~ 1020. Note ESP32 will be closer to 4096 with its 12bit ADC

+ */

+MagneticSensorAnalog sensor = MagneticSensorAnalog(A1, 14, 1020);

+

+void setup() {

+ // monitoring port

+ Serial.begin(115200);

+

+ // initialise magnetic sensor hardware

+ sensor.init();

+

+ Serial.println("Sensor ready");

+ _delay(1000);

+}

+

+int max_count = 0;

+int min_count = 100000;

+

+void loop() {

+

+ // keep track of min and max

+ if(sensor.raw_count > max_count) max_count = sensor.raw_count;

+ else if(sensor.raw_count < min_count) min_count = sensor.raw_count;

+

+ // display the raw count, and max and min raw count

+ Serial.print("angle:");

+ Serial.print(sensor.getAngle());

+ Serial.print("\t, raw:");

+ Serial.print(sensor.raw_count);

+ Serial.print("\t, min:");

+ Serial.print(min_count);

+ Serial.print("\t, max:");

+ Serial.println(max_count);

+ delay(100);

+}

\ No newline at end of file

diff --git a/examples/utils/sensor_test/magnetic_sensors/magnetic_sensor_analog_example/magnetic_sensor_analog_example.ino b/examples/utils/sensor_test/magnetic_sensors/magnetic_sensor_analog_example/magnetic_sensor_analog/magnetic_sensor_analog.ino

similarity index 99%

rename from examples/utils/sensor_test/magnetic_sensors/magnetic_sensor_analog_example/magnetic_sensor_analog_example.ino

rename to examples/utils/sensor_test/magnetic_sensors/magnetic_sensor_analog_example/magnetic_sensor_analog/magnetic_sensor_analog.ino

index ef34127c..40d47ba8 100644

--- a/examples/utils/sensor_test/magnetic_sensors/magnetic_sensor_analog_example/magnetic_sensor_analog_example.ino

+++ b/examples/utils/sensor_test/magnetic_sensors/magnetic_sensor_analog_example/magnetic_sensor_analog/magnetic_sensor_analog.ino

@@ -1,6 +1,7 @@

#include

+

/**

* Magnetic sensor reading analog voltage on pin A1. This voltage is proportional to rotation position.

* Tested on AS5600 magnetic sensor running in 'analog mode'. Note AS5600 works better in 'i2C mode' (less noise) but only supports one sensor per i2c bus.

@@ -28,4 +29,4 @@ void loop() {

Serial.print(sensor.getAngle());

Serial.print("\t");

Serial.println(sensor.getVelocity());

-}

+}

\ No newline at end of file

diff --git a/examples/utils/sensor_test/magnetic_sensors/magnetic_sensor_pwm_example/find_raw_min_max/find_raw_min_max.ino b/examples/utils/sensor_test/magnetic_sensors/magnetic_sensor_pwm_example/find_raw_min_max/find_raw_min_max.ino

new file mode 100644

index 00000000..a88b7186

--- /dev/null

+++ b/examples/utils/sensor_test/magnetic_sensors/magnetic_sensor_pwm_example/find_raw_min_max/find_raw_min_max.ino

@@ -0,0 +1,44 @@

+#include

+

+

+/**

+ * An example to find out the raw max and min count to be provided to the constructor

+ * SPin your motor/sensor/magnet to see what is the maximum output of the sensor and what is the minimum value

+ * And replace values 4 and 904 with new values. Once when you replace them make sure there is no jump in the angle reading sensor.getAngle().

+ * If there is a jump that means you can still find better values.

+ */

+MagneticSensorPWM sensor = MagneticSensorPWM(2, 4, 904);

+void doPWM(){sensor.handlePWM();}

+

+void setup() {

+ // monitoring port

+ Serial.begin(115200);

+

+ // initialise magnetic sensor hardware

+ sensor.init();

+ // comment out to use sensor in blocking (non-interrupt) way

+ sensor.enableInterrupt(doPWM);

+

+ Serial.println("Sensor ready");

+ _delay(1000);

+}

+

+int max_pulse= 0;

+int min_pulse = 10000;

+

+void loop() {

+

+ // keep track of min and max

+ if(sensor.pulse_length_us > max_pulse) max_pulse = sensor.pulse_length_us;

+ else if(sensor.pulse_length_us < min_pulse) min_pulse = sensor.pulse_length_us;

+

+ // display the raw count, and max and min raw count

+ Serial.print("angle:");

+ Serial.print(sensor.getAngle());

+ Serial.print("\t, raw:");

+ Serial.print(sensor.pulse_length_us);

+ Serial.print("\t, min:");

+ Serial.print(min_pulse);

+ Serial.print("\t, max:");

+ Serial.println(max_pulse);

+}

diff --git a/examples/utils/sensor_test/magnetic_sensors/magnetic_sensor_pwm_example/magnetic_sensor_pwm/magnetic_sensor_pwm.ino b/examples/utils/sensor_test/magnetic_sensors/magnetic_sensor_pwm_example/magnetic_sensor_pwm/magnetic_sensor_pwm.ino

new file mode 100644

index 00000000..15a1f557

--- /dev/null

+++ b/examples/utils/sensor_test/magnetic_sensors/magnetic_sensor_pwm_example/magnetic_sensor_pwm/magnetic_sensor_pwm.ino

@@ -0,0 +1,33 @@

+#include

+

+

+/**

+ * Magnetic sensor reading pwm signal on pin 2. The pwm duty cycle is proportional to the sensor angle.

+ *

+ * MagneticSensorPWM(uint8_t MagneticSensorPWM, int _min, int _max)

+ * - pinPWM - the pin that is reading the pwm from magnetic sensor

+ * - min_raw_count - the smallest expected reading. Whilst you might expect it to be 0 it is often ~5. Getting this wrong results in a small click once per revolution

+ * - max_raw_count - the largest value read. whilst you might expect it to be 1kHz = 1000 it is often ~910. depending on the exact frequency and saturation

+ */

+MagneticSensorPWM sensor = MagneticSensorPWM(2, 4, 904);

+void doPWM(){sensor.handlePWM();}

+

+void setup() {

+ // monitoring port

+ Serial.begin(115200);

+

+ // initialise magnetic sensor hardware

+ sensor.init();

+ // comment out to use sensor in blocking (non-interrupt) way

+ sensor.enableInterrupt(doPWM);

+

+ Serial.println("Sensor ready");

+ _delay(1000);

+}

+

+void loop() {

+ // display the angle and the angular velocity to the terminal

+ Serial.print(sensor.getAngle());

+ Serial.print("\t");

+ Serial.println(sensor.getVelocity());

+}

diff --git a/examples/utils/sensor_test/magnetic_sensors/magnetic_sensor_pwm_example/magnetic_sensor_pwm_software_interrupt/magnetic_sensor_pwm_software_interrupt.ino b/examples/utils/sensor_test/magnetic_sensors/magnetic_sensor_pwm_example/magnetic_sensor_pwm_software_interrupt/magnetic_sensor_pwm_software_interrupt.ino

new file mode 100644

index 00000000..6b19a9fa

--- /dev/null

+++ b/examples/utils/sensor_test/magnetic_sensors/magnetic_sensor_pwm_example/magnetic_sensor_pwm_software_interrupt/magnetic_sensor_pwm_software_interrupt.ino

@@ -0,0 +1,39 @@

+#include

+

+// software interrupt library

+#include

+#include

+

+/**

+ * Magnetic sensor reading analog voltage on pin which does not have hardware interrupt support. Such as A0.

+ *

+ * MagneticSensorPWM(uint8_t MagneticSensorPWM, int _min, int _max)

+ * - pinPWM - the pin that is reading the pwm from magnetic sensor

+ * - min_raw_count - the smallest expected reading. Whilst you might expect it to be 0 it is often ~5. Getting this wrong results in a small click once per revolution

+ * - max_raw_count - the largest value read. whilst you might expect it to be 1kHz = 1000 it is often ~910. depending on the exact frequency and saturation

+ */

+MagneticSensorPWM sensor = MagneticSensorPWM(A0, 4, 904);

+void doPWM(){sensor.handlePWM();}

+

+// encoder interrupt init

+PciListenerImp listenerPWM(sensor.pinPWM, doPWM);

+

+void setup() {

+ // monitoring port

+ Serial.begin(115200);

+

+ // initialise magnetic sensor hardware

+ sensor.init();

+ // comment out to use sensor in blocking (non-interrupt) way

+ PciManager.registerListener(&listenerPWM);

+

+ Serial.println("Sensor ready");

+ _delay(1000);

+}

+

+void loop() {

+ // display the angle and the angular velocity to the terminal

+ Serial.print(sensor.getAngle());

+ Serial.print("\t");

+ Serial.println(sensor.getVelocity());

+}

diff --git a/keywords.txt b/keywords.txt

index 9ec297c8..77152a36 100644

--- a/keywords.txt

+++ b/keywords.txt

@@ -8,6 +8,7 @@ HallSensors KEYWORD1

MagneticSensorSPI KEYWORD1

MagneticSensorI2C KEYWORD1

MagneticSensorAnalog KEYWORD1

+MagneticSensorPWM KEYWORD1

BLDCDriver3PWM KEYWORD1

BLDCDriver6PWM KEYWORD1

BLDCDriver KEYWORD1

@@ -92,6 +93,8 @@ scalar KEYWORD2

pid KEYWORD2

lpf KEYWORD2

motor KEYWORD2

+handlePWM KEYWORD2

+enableInterrupt KEYWORD2

@@ -119,6 +122,8 @@ sensor_offset KEYWORD2

zero_electric_angle KEYWORD2

verbose KEYWORD2

decimal_places KEYWORD2

+phase_resistance KEYWORD2

+modulation_centered KEYWORD2

@@ -159,8 +164,8 @@ pinB KEYWORD2

pinC KEYWORD2

index_pin KEYWORD2

-INTERN KEYWORD2

-EXTERN KEYWORD2

+USE_INTERN KEYWORD2

+USE_EXTERN KEYWORD2

DISABLE KEYWORD2

ENABLE KEYWORD2

SpaceVectorPWM KEYWORD2

diff --git a/library.properties b/library.properties

index 062ff725..af8559f1 100644

--- a/library.properties

+++ b/library.properties

@@ -1,5 +1,5 @@

name=Simple FOC

-version=2.1

+version=2.1.1

author=Simplefoc

maintainer=Simplefoc

sentence=A library demistifying FOC for BLDC motors

diff --git a/src/BLDCMotor.cpp b/src/BLDCMotor.cpp

index 76dc7032..9c2f89c0 100644

--- a/src/BLDCMotor.cpp

+++ b/src/BLDCMotor.cpp

@@ -98,8 +98,11 @@ int BLDCMotor::initFOC( float zero_electric_offset, Direction _sensor_direction

// sensor and motor alignment - can be skipped

// by setting motor.sensor_direction and motor.zero_electric_angle

_delay(500);

- if(sensor) exit_flag *= alignSensor();

- else if(monitor_port) monitor_port->println(F("MOT: No sensor."));

+ if(sensor){

+ exit_flag *= alignSensor();

+ // added the shaft_angle update

+ shaft_angle = sensor->getAngle();

+ }else if(monitor_port) monitor_port->println(F("MOT: No sensor."));

// aligning the current sensor - can be skipped

// checks if driver phases are the same as current sense phases

@@ -244,13 +247,14 @@ int BLDCMotor::absoluteZeroSearch() {

// Iterative function looping FOC algorithm, setting Uq on the Motor

// The faster it can be run the better

void BLDCMotor::loopFOC() {

- // if disabled do nothing

- if(!enabled) return;

// if open-loop do nothing

if( controller==MotionControlType::angle_openloop || controller==MotionControlType::velocity_openloop ) return;

-

// shaft angle

- shaft_angle = shaftAngle();

+ shaft_angle = shaftAngle(); // read value even if motor is disabled to keep the monitoring updated

+

+ // if disabled do nothing

+ if(!enabled) return;

+

// electrical angle - need shaftAngle to be called first

electrical_angle = electricalAngle();

@@ -295,6 +299,10 @@ void BLDCMotor::loopFOC() {

// - needs to be called iteratively it is asynchronous function

// - if target is not set it uses motor.target value

void BLDCMotor::move(float new_target) {

+

+ // get angular velocity

+ shaft_velocity = shaftVelocity(); // read value even if motor is disabled to keep the monitoring updated

+

// if disabled do nothing

if(!enabled) return;

// downsampling (optional)

@@ -302,8 +310,6 @@ void BLDCMotor::move(float new_target) {

motion_cnt = 0;

// set internal target variable

if(_isset(new_target)) target = new_target;

- // get angular velocity

- shaft_velocity = shaftVelocity();

switch (controller) {

case MotionControlType::torque:

diff --git a/src/SimpleFOC.h b/src/SimpleFOC.h

index 6b7afbb2..eee0297b 100644

--- a/src/SimpleFOC.h

+++ b/src/SimpleFOC.h

@@ -102,6 +102,7 @@ void loop() {

#include "sensors/MagneticSensorSPI.h"

#include "sensors/MagneticSensorI2C.h"

#include "sensors/MagneticSensorAnalog.h"

+#include "sensors/MagneticSensorPWM.h"

#include "sensors/HallSensor.h"

#include "drivers/BLDCDriver3PWM.h"

#include "drivers/BLDCDriver6PWM.h"

diff --git a/src/StepperMotor.cpp b/src/StepperMotor.cpp

index 604914ed..183c2c65 100644

--- a/src/StepperMotor.cpp

+++ b/src/StepperMotor.cpp

@@ -96,8 +96,11 @@ int StepperMotor::initFOC( float zero_electric_offset, Direction _sensor_direct

// sensor and motor alignment - can be skipped

// by setting motor.sensor_direction and motor.zero_electric_angle

_delay(500);

- if(sensor) exit_flag = alignSensor();

- else if(monitor_port) monitor_port->println(F("MOT: No sensor."));

+ if(sensor){

+ exit_flag *= alignSensor();

+ // added the shaft_angle update

+ shaft_angle = sensor->getAngle();

+ }else if(monitor_port) monitor_port->println(F("MOT: No sensor."));

if(exit_flag){

if(monitor_port) monitor_port->println(F("MOT: Ready."));

@@ -213,13 +216,14 @@ int StepperMotor::absoluteZeroSearch() {

// Iterative function looping FOC algorithm, setting Uq on the Motor

// The faster it can be run the better

void StepperMotor::loopFOC() {

- // if disabled do nothing

- if(!enabled) return;

// if open-loop do nothing

if( controller==MotionControlType::angle_openloop || controller==MotionControlType::velocity_openloop ) return;

-

// shaft angle

shaft_angle = shaftAngle();

+

+ // if disabled do nothing

+ if(!enabled) return;

+

electrical_angle = electricalAngle();

// set the phase voltage - FOC heart function :)

@@ -232,6 +236,8 @@ void StepperMotor::loopFOC() {

// - needs to be called iteratively it is asynchronous function

// - if target is not set it uses motor.target value

void StepperMotor::move(float new_target) {

+ // get angular velocity

+ shaft_velocity = shaftVelocity();

// if disabled do nothing

if(!enabled) return;

// downsampling (optional)

@@ -239,8 +245,6 @@ void StepperMotor::move(float new_target) {

motion_cnt = 0;

// set internal target variable

if(_isset(new_target) ) target = new_target;

- // get angular velocity

- shaft_velocity = shaftVelocity();

// choose control loop

switch (controller) {

case MotionControlType::torque:

diff --git a/src/common/base_classes/CurrentSense.cpp b/src/common/base_classes/CurrentSense.cpp

index accaebb3..2cec8dd5 100644

--- a/src/common/base_classes/CurrentSense.cpp

+++ b/src/common/base_classes/CurrentSense.cpp

@@ -17,8 +17,12 @@ float CurrentSense::getDCCurrent(float motor_electrical_angle){

i_alpha = current.a;

i_beta = _1_SQRT3 * current.a + _2_SQRT3 * current.b;

}else{

- i_alpha = 2*(current.a - (current.b - current.c))/3.0;

- i_beta = _2_SQRT3 *( current.b - current.c );

+ // signal filtering using identity a + b + c = 0. Assumes measurement error is normally distributed.

+ float mid = (1.f/3) * (current.a + current.b + current.c);

+ float a = current.a - mid;

+ float b = current.b - mid;

+ i_alpha = a;

+ i_beta = _1_SQRT3 * a + _2_SQRT3 * b;

}

// if motor angle provided function returns signed value of the current

@@ -44,9 +48,13 @@ DQCurrent_s CurrentSense::getFOCCurrents(float angle_el){

// if only two measured currents

i_alpha = current.a;

i_beta = _1_SQRT3 * current.a + _2_SQRT3 * current.b;

- }else{

- i_alpha = 0.6666667*(current.a - (current.b - current.c));

- i_beta = _2_SQRT3 *( current.b - current.c );

+ } else {

+ // signal filtering using identity a + b + c = 0. Assumes measurement error is normally distributed.

+ float mid = (1.f/3) * (current.a + current.b + current.c);

+ float a = current.a - mid;

+ float b = current.b - mid;

+ i_alpha = a;

+ i_beta = _1_SQRT3 * a + _2_SQRT3 * b;

}

// calculate park transform

diff --git a/src/common/base_classes/FOCMotor.h b/src/common/base_classes/FOCMotor.h

index c918b052..37c5b260 100644

--- a/src/common/base_classes/FOCMotor.h

+++ b/src/common/base_classes/FOCMotor.h

@@ -169,7 +169,7 @@ class FOCMotor

LowPassFilter LPF_current_q{DEF_CURR_FILTER_Tf};//!< parameter determining the current Low pass filter configuration

LowPassFilter LPF_current_d{DEF_CURR_FILTER_Tf};//!< parameter determining the current Low pass filter configuration

PIDController PID_velocity{DEF_PID_VEL_P,DEF_PID_VEL_I,DEF_PID_VEL_D,DEF_PID_VEL_RAMP,DEF_PID_VEL_LIMIT};//!< parameter determining the velocity PID configuration

- PIDController P_angle{DEF_P_ANGLE_P,0,0,1e10,DEF_VEL_LIM}; //!< parameter determining the position PID configuration

+ PIDController P_angle{DEF_P_ANGLE_P,0,0,0,DEF_VEL_LIM}; //!< parameter determining the position PID configuration

LowPassFilter LPF_velocity{DEF_VEL_FILTER_Tf};//!< parameter determining the velocity Low pass filter configuration

LowPassFilter LPF_angle{0.0};//!< parameter determining the angle low pass filter configuration

unsigned int motion_downsample = DEF_MOTION_DOWNSMAPLE; //!< parameter defining the ratio of downsampling for move commad

diff --git a/src/common/base_classes/Sensor.h b/src/common/base_classes/Sensor.h

index c7771a05..3b219401 100644

--- a/src/common/base_classes/Sensor.h

+++ b/src/common/base_classes/Sensor.h

@@ -15,8 +15,8 @@ enum Direction{

* Pullup configuration structure

*/

enum Pullup{

- INTERN, //!< Use internal pullups

- EXTERN //!< Use external pullups

+ USE_INTERN, //!< Use internal pullups

+ USE_EXTERN //!< Use external pullups

};

/**

@@ -43,4 +43,4 @@ class Sensor{

long velocity_calc_timestamp=0; //!< last velocity calculation timestamp

};

-#endif

\ No newline at end of file

+#endif

diff --git a/src/common/defaults.h b/src/common/defaults.h

index 9c8cee3a..71f39098 100644

--- a/src/common/defaults.h

+++ b/src/common/defaults.h

@@ -23,7 +23,7 @@

#define DEF_PID_CURR_P 3 //!< default PID controller P value

#define DEF_PID_CURR_I 300.0 //!< default PID controller I value

#define DEF_PID_CURR_D 0.0 //!< default PID controller D value

-#define DEF_PID_CURR_RAMP 1e11 //!< default PID controller voltage ramp value

+#define DEF_PID_CURR_RAMP 0 //!< default PID controller voltage ramp value

#define DEF_PID_CURR_LIMIT (DEF_POWER_SUPPLY) //!< default PID controller voltage limit

#define DEF_CURR_FILTER_Tf 0.005 //!< default currnet filter time constant

#endif

diff --git a/src/common/pid.cpp b/src/common/pid.cpp

index a910556f..5290d814 100644

--- a/src/common/pid.cpp

+++ b/src/common/pid.cpp

@@ -40,13 +40,15 @@ float PIDController::operator() (float error){

// antiwindup - limit the output variable

output = _constrain(output, -limit, limit);

- // limit the acceleration by ramping the output

- float output_rate = (output - output_prev)/Ts;

- if (output_rate > output_ramp)

- output = output_prev + output_ramp*Ts;

- else if (output_rate < -output_ramp)

- output = output_prev - output_ramp*Ts;

-

+ // if output ramp defined

+ if(output_ramp > 0){

+ // limit the acceleration by ramping the output

+ float output_rate = (output - output_prev)/Ts;

+ if (output_rate > output_ramp)

+ output = output_prev + output_ramp*Ts;

+ else if (output_rate < -output_ramp)

+ output = output_prev - output_ramp*Ts;

+ }

// saving for the next pass

integral_prev = integral;

output_prev = output;

diff --git a/src/communication/Commander.cpp b/src/communication/Commander.cpp

index 6ee08d07..8e1cb051 100644

--- a/src/communication/Commander.cpp

+++ b/src/communication/Commander.cpp

@@ -1,11 +1,14 @@

#include "Commander.h"

-Commander::Commander(Stream& serial){

+Commander::Commander(Stream& serial, char eol, bool echo){

com_port = &serial;

+ this->eol = eol;

+ this->echo = echo;

}

-Commander::Commander(){

- // do nothing

+Commander::Commander(char eol, bool echo){

+ this->eol = eol;

+ this->echo = echo;

}

@@ -19,33 +22,24 @@ void Commander::add(char id, CommandCallback onCommand, char* label ){

void Commander::run(){

if(!com_port) return;

- // a string to hold incoming data

- while (com_port->available()) {

- // get the new byte:

- received_chars[rec_cnt] = (char)com_port->read();

- // end of user input

- if (received_chars[rec_cnt++] == '\n') {

- // execute the user command

- run(received_chars);

-

- // reset the command buffer

- received_chars[0] = 0;

- rec_cnt=0;

- }

- }

+ run(*com_port, eol);

}

-void Commander::run(Stream& serial){

+void Commander::run(Stream& serial, char eol){

Stream* tmp = com_port; // save the serial instance

- // use the new serial instance to output if not available the one linked in constructor

- if(!tmp) com_port = &serial;

+ char eol_tmp = this->eol;

+ this->eol = eol;

+ com_port = &serial;

// a string to hold incoming data

while (serial.available()) {

// get the new byte:

- received_chars[rec_cnt] = (char)serial.read();

+ int ch = serial.read();

+ received_chars[rec_cnt++] = (char)ch;

// end of user input

- if (received_chars[rec_cnt++] == '\n') {

+ if(echo)

+ print((char)ch);

+ if (isSentinel(ch)) {

// execute the user command

run(received_chars);

@@ -53,9 +47,14 @@ void Commander::run(Stream& serial){

received_chars[0] = 0;

rec_cnt=0;

}

+ if (rec_cnt>=MAX_COMMAND_LENGTH) { // prevent buffer overrun if message is too long

+ received_chars[0] = 0;

+ rec_cnt=0;

+ }

}

com_port = tmp; // reset the instance to the internal value

+ this->eol = eol_tmp;

}

void Commander::run(char* user_input){

@@ -71,7 +70,7 @@ void Commander::run(char* user_input){

}

break;

case CMD_VERBOSE:

- if(user_input[1] != '\n') verbose = (VerboseMode)atoi(&user_input[1]);

+ if(!isSentinel(user_input[1])) verbose = (VerboseMode)atoi(&user_input[1]);

printVerbose(F("Verb:"));

switch (verbose){

case VerboseMode::nothing:

@@ -84,7 +83,7 @@ void Commander::run(char* user_input){

}

break;

case CMD_DECIMAL:

- if(user_input[1] != '\n') decimal_places = atoi(&user_input[1]);

+ if(!isSentinel(user_input[1])) decimal_places = atoi(&user_input[1]);

printVerbose(F("Decimal:"));

println(decimal_places);

break;

@@ -100,14 +99,25 @@ void Commander::run(char* user_input){

}

void Commander::motor(FOCMotor* motor, char* user_command) {

+

+ // if target setting

+ if(isDigit(user_command[0]) || user_command[0] == '-' || user_command[0] == '+'){

+ printVerbose(F("Target: "));

+ motor->target = atof(user_command);

+ println(motor->target);

+ return;

+ }

+

// parse command letter

char cmd = user_command[0];

char sub_cmd = user_command[1];

+ // check if there is a subcommand or not

int value_index = (sub_cmd >= 'A' && sub_cmd <= 'Z') ? 2 : 1;

// check if get command

- bool GET = user_command[value_index] == '\n';

+ bool GET = isSentinel(user_command[value_index]);

// parse command values

- float value = atof(&user_command[value_index]);

+ float value = atof(&user_command[value_index]);

+

// a bit of optimisation of variable memory for Arduino UNO (atmega328)

switch(cmd){

@@ -149,10 +159,8 @@ void Commander::motor(FOCMotor* motor, char* user_command) {

printVerbose(F("curr: "));

if(!GET){

motor->current_limit = value;

- // if phase resistance is set, change the voltage limit as well.

- if(_isset(motor->phase_resistance)) motor->voltage_limit = value*motor->phase_resistance;

// if phase resistance specified or the current control is on set the current limit to the velocity PID

- if(_isset(motor->phase_resistance) || motor->torque_controller != TorqueControlType::voltage ) motor->PID_velocity.limit = value;

+ if(_isset(motor->phase_resistance) || motor->torque_controller != TorqueControlType::voltage ) motor->PID_velocity.limit = value;

}

println(motor->current_limit);

break;

@@ -170,16 +178,16 @@ void Commander::motor(FOCMotor* motor, char* user_command) {

}

break;

case CMD_MOTION_TYPE:

- printVerbose(F("Motion: "));

+ printVerbose(F("Motion:"));

switch(sub_cmd){

case SCMD_DOWNSAMPLE:

- printVerbose(F("downsample: "));

+ printVerbose(F(" downsample: "));

if(!GET) motor->motion_downsample = value;

println((int)motor->motion_downsample);

break;

default:

// change control type

- if(!GET && value >= 0 && (int)value < 5)// if set command

+ if(!GET && value >= 0 && (int)value < 5) // if set command

motor->controller = (MotionControlType)value;

switch(motor->controller){

case MotionControlType::torque:

@@ -224,6 +232,38 @@ void Commander::motor(FOCMotor* motor, char* user_command) {

if(!GET) (bool)value ? motor->enable() : motor->disable();

println(motor->enabled);

break;

+ case CMD_PWMMOD:

+ // PWM modulation change

+ printVerbose(F("PWM Mod | "));

+ switch (sub_cmd){

+ case SCMD_PWMMOD_TYPE: // zero offset

+ printVerbose(F("type: "));

+ if(!GET) motor->foc_modulation = (FOCModulationType)value;

+ switch(motor->foc_modulation){

+ case FOCModulationType::SinePWM:

+ println(F("SinePWM"));

+ break;

+ case FOCModulationType::SpaceVectorPWM:

+ println(F("SVPWM"));

+ break;

+ case FOCModulationType::Trapezoid_120:

+ println(F("Trap 120"));

+ break;

+ case FOCModulationType::Trapezoid_150:

+ println(F("Trap 150"));

+ break;

+ }

+ break;

+ case SCMD_PWMMOD_CENTER: // centered modulation

+ printVerbose(F("center: "));

+ if(!GET) motor->modulation_centered = value;

+ println(motor->modulation_centered);

+ break;

+ default:

+ printError();

+ break;

+ }

+ break;

case CMD_RESIST:

// enable/disable

printVerbose(F("R phase: "));

@@ -271,7 +311,7 @@ void Commander::motor(FOCMotor* motor, char* user_command) {

break;

case 2: // get voltage d

printVerbose(F("Vd: "));

- println(motor->voltage.q);

+ println(motor->voltage.d);

break;

case 3: // get current q

printVerbose(F("Cq: "));

@@ -279,7 +319,7 @@ void Commander::motor(FOCMotor* motor, char* user_command) {

break;

case 4: // get current d

printVerbose(F("Cd: "));

- println(motor->current.q);

+ println(motor->current.d);

break;

case 5: // get velocity

printVerbose(F("vel: "));

@@ -289,6 +329,22 @@ void Commander::motor(FOCMotor* motor, char* user_command) {

printVerbose(F("angle: "));

println(motor->shaft_angle);

break;

+ case 7: // get all states

+ printVerbose(F("all: "));

+ print(motor->target);

+ print(";");

+ print(motor->voltage.q);

+ print(";");

+ print(motor->voltage.d);

+ print(";");

+ print(motor->current.q);

+ print(";");

+ print(motor->current.d);

+ print(";");

+ print(motor->shaft_velocity);

+ print(";");

+ println(motor->shaft_angle);

+ break;

default:

printError();

break;

@@ -306,7 +362,7 @@ void Commander::motor(FOCMotor* motor, char* user_command) {

case SCMD_SET:

if(!GET) motor->monitor_variables = (uint8_t) 0;

for(int i = 0; i < 7; i++){

- if(user_command[value_index+i] == '\n') break;

+ if(isSentinel(user_command[value_index+i])) break;

if(!GET) motor->monitor_variables |= (user_command[value_index+i] - '0') << (6-i);

print( (user_command[value_index+i] - '0') );

}

@@ -317,16 +373,15 @@ void Commander::motor(FOCMotor* motor, char* user_command) {

break;

}

break;

- default: // target change

- printVerbose(F("Target: "));

- motor->target = atof(user_command);

- println(motor->target);

+ default: // unknown cmd

+ printVerbose(F("unknown cmd "));

+ printError();

}

}

void Commander::pid(PIDController* pid, char* user_cmd){

char cmd = user_cmd[0];

- bool GET = user_cmd[1] == '\n';

+ bool GET = isSentinel(user_cmd[1]);

float value = atof(&user_cmd[1]);

switch (cmd){

@@ -363,7 +418,7 @@ void Commander::pid(PIDController* pid, char* user_cmd){

void Commander::lpf(LowPassFilter* lpf, char* user_cmd){

char cmd = user_cmd[0];

- bool GET = user_cmd[1] == '\n';

+ bool GET = isSentinel(user_cmd[1]);

float value = atof(&user_cmd[1]);

switch (cmd){

@@ -379,11 +434,21 @@ void Commander::lpf(LowPassFilter* lpf, char* user_cmd){

}

void Commander::scalar(float* value, char* user_cmd){

- bool GET = user_cmd[0] == '\n';

+ bool GET = isSentinel(user_cmd[0]);

if(!GET) *value = atof(user_cmd);

println(*value);

}

+bool Commander::isSentinel(char ch)

+{

+ if(ch == eol)

+ return true;

+ else if (ch == '\r')

+ {

+ printVerbose(F("Warn: \\r detected! \n"));

+ }

+ return false;

+}

void Commander::print(const int number){

if( !com_port || verbose == VerboseMode::nothing ) return;

diff --git a/src/communication/Commander.h b/src/communication/Commander.h

index 0b07b707..aaa55b11 100644

--- a/src/communication/Commander.h

+++ b/src/communication/Commander.h

@@ -7,6 +7,10 @@

#include "../common/lowpass_filter.h"

#include "commands.h"

+

+#define MAX_COMMAND_LENGTH 20

+

+

// Commander verbose display to the user type

enum VerboseMode{

nothing = 0, // display nothing - good for monitoring

@@ -38,9 +42,11 @@ class Commander

* Also if the function run() is used it uses this serial instance to read the serial for user commands

*

* @param serial - Serial com port instance

+ * @param eol - the end of line sentinel character

+ * @param echo - echo last typed character (for command line feedback)

*/

- Commander(Stream &serial);

- Commander();

+ Commander(Stream &serial, char eol = '\n', bool echo = false);

+ Commander(char eol = '\n', bool echo = false);

/**

* Function reading the serial port and firing callbacks that have been added to the commander

@@ -61,9 +67,10 @@ class Commander

* '#' - Number of decimal places

* '?' - Scan command - displays all the labels of attached nodes

*

- * @param reader - Stream to read user input

+ * @param reader - temporary stream to read user input

+ * @param eol - temporary end of line sentinel

*/

- void run(Stream &reader);

+ void run(Stream &reader, char eol = '\n');

/**

* Function reading the string of user input and firing callbacks that have been added to the commander

* once the user has requested them - when he sends the command

@@ -91,7 +98,8 @@ class Commander

// monitoring functions

Stream* com_port = nullptr; //!< Serial terminal variable if provided

-

+ char eol = '\n'; //!< end of line sentinel character

+ bool echo = false; //!< echo last typed character (for command line feedback)

/**

*

* FOC motor (StepperMotor and BLDCMotor) command interface

@@ -174,7 +182,7 @@ class Commander

int call_count = 0;//!< number callbacks that are subscribed

// helping variable for serial communication reading

- char received_chars[20] = {0}; //!< so far received user message - waiting for newline

+ char received_chars[MAX_COMMAND_LENGTH] = {0}; //!< so far received user message - waiting for newline

int rec_cnt = 0; //!< number of characters receives

// serial printing functions

@@ -194,6 +202,7 @@ class Commander

* @param message - number to be printed

* @param newline - if needs lewline (1) otherwise (0)

*/

+

void print(const float number);

void print(const int number);

void print(const char* message);

@@ -206,6 +215,7 @@ class Commander

void println(const char message);

void printError();

+ bool isSentinel(char ch);

};

diff --git a/src/communication/commands.h b/src/communication/commands.h

index 69405629..3ba6cdde 100644

--- a/src/communication/commands.h

+++ b/src/communication/commands.h

@@ -15,6 +15,7 @@

#define CMD_SENSOR 'S' //!< sensor offsets

#define CMD_MONITOR 'M' //!< monitoring

#define CMD_RESIST 'R' //!< motor phase resistance

+ #define CMD_PWMMOD 'W' //!< pwm modulation

// commander configuration

#define CMD_SCAN '?' //!< command scaning the network - only for commander

@@ -41,5 +42,9 @@

#define SCMD_CLEAR 'C' //!< Clear all monitored variables

#define SCMD_GET 'G' //!< Get variable only one value

#define SCMD_SET 'S' //!< Set variables to be monitored

-

+

+ #define SCMD_PWMMOD_TYPE 'T' //!<< Pwm modulation type

+ #define SCMD_PWMMOD_CENTER 'C' //!<< Pwm modulation center flag

+

+

#endif

\ No newline at end of file

diff --git a/src/current_sense/InlineCurrentSense.cpp b/src/current_sense/InlineCurrentSense.cpp

index d5d10881..2e9c4421 100644

--- a/src/current_sense/InlineCurrentSense.cpp

+++ b/src/current_sense/InlineCurrentSense.cpp

@@ -28,21 +28,23 @@ void InlineCurrentSense::init(){

}

// Function finding zero offsets of the ADC

void InlineCurrentSense::calibrateOffsets(){

+ const int calibration_rounds = 1000;

+

// find adc offset = zero current voltage

- offset_ia =0;

- offset_ib= 0;

- offset_ic= 0;

+ offset_ia = 0;

+ offset_ib = 0;

+ offset_ic = 0;

// read the adc voltage 1000 times ( arbitrary number )

- for (int i = 0; i < 1000; i++) {

+ for (int i = 0; i < calibration_rounds; i++) {

offset_ia += _readADCVoltage(pinA);

offset_ib += _readADCVoltage(pinB);

if(_isset(pinC)) offset_ic += _readADCVoltage(pinC);

_delay(1);

}

// calculate the mean offsets

- offset_ia = offset_ia / 1000.0;

- offset_ib = offset_ib / 1000.0;

- if(_isset(pinC)) offset_ic = offset_ic / 500.0;

+ offset_ia = offset_ia / calibration_rounds;

+ offset_ib = offset_ib / calibration_rounds;

+ if(_isset(pinC)) offset_ic = offset_ic / calibration_rounds;

}

// read all three phase currents (if possible 2 or 3)

diff --git a/src/current_sense/InlineCurrentSense.h b/src/current_sense/InlineCurrentSense.h

index 64c658d1..da46d104 100644

--- a/src/current_sense/InlineCurrentSense.h

+++ b/src/current_sense/InlineCurrentSense.h

@@ -29,9 +29,9 @@ class InlineCurrentSense: public CurrentSense{

// ADC measuremnet gain for each phase

// support for different gains for different phases of more commonly - inverted phase currents

// this should be automated later

- int gain_a; //!< phase A gain

- int gain_b; //!< phase B gain

- int gain_c; //!< phase C gain

+ float gain_a; //!< phase A gain

+ float gain_b; //!< phase B gain

+ float gain_c; //!< phase C gain

private:

diff --git a/src/drivers/BLDCDriver3PWM.cpp b/src/drivers/BLDCDriver3PWM.cpp

index 87eb7f5b..11215863 100644

--- a/src/drivers/BLDCDriver3PWM.cpp

+++ b/src/drivers/BLDCDriver3PWM.cpp

@@ -41,9 +41,6 @@ void BLDCDriver3PWM::disable()

// init hardware pins

int BLDCDriver3PWM::init() {

- // a bit of separation

- _delay(1000);

-

// PWM pins

pinMode(pwmA, OUTPUT);

pinMode(pwmB, OUTPUT);

diff --git a/src/drivers/BLDCDriver6PWM.cpp b/src/drivers/BLDCDriver6PWM.cpp

index 013e6415..d51eec0a 100644

--- a/src/drivers/BLDCDriver6PWM.cpp

+++ b/src/drivers/BLDCDriver6PWM.cpp

@@ -24,7 +24,7 @@ BLDCDriver6PWM::BLDCDriver6PWM(int phA_h,int phA_l,int phB_h,int phB_l,int phC_h

// enable motor driver

void BLDCDriver6PWM::enable(){

// enable_pin the driver - if enable_pin pin available

- if ( _isset(enable_pin) ) digitalWrite(enable_pin, HIGH);

+ if ( _isset(enable_pin) ) digitalWrite(enable_pin, enable_active_high);

// set zero to PWM

setPwm(0, 0, 0);

}

@@ -35,15 +35,13 @@ void BLDCDriver6PWM::disable()

// set zero to PWM

setPwm(0, 0, 0);

// disable the driver - if enable_pin pin available

- if ( _isset(enable_pin) ) digitalWrite(enable_pin, LOW);

+ if ( _isset(enable_pin) ) digitalWrite(enable_pin, !enable_active_high);

}

// init hardware pins

int BLDCDriver6PWM::init() {

- // a bit of separation

- _delay(1000);

-

+

// PWM pins

pinMode(pwmA_h, OUTPUT);

pinMode(pwmB_h, OUTPUT);

@@ -82,4 +80,4 @@ void BLDCDriver6PWM::setPwm(float Ua, float Ub, float Uc) {

// Set voltage to the pwm pin

void BLDCDriver6PWM::setPhaseState(int sa, int sb, int sc) {

// TODO implement disabling

-}

\ No newline at end of file

+}

diff --git a/src/drivers/BLDCDriver6PWM.h b/src/drivers/BLDCDriver6PWM.h

index 68487370..cee37d64 100644

--- a/src/drivers/BLDCDriver6PWM.h

+++ b/src/drivers/BLDCDriver6PWM.h

@@ -37,6 +37,7 @@ class BLDCDriver6PWM: public BLDCDriver

int pwmB_h,pwmB_l; //!< phase B pwm pin number

int pwmC_h,pwmC_l; //!< phase C pwm pin number

int enable_pin; //!< enable pin number

+ bool enable_active_high = true;

float dead_zone; //!< a percentage of dead-time(zone) (both high and low side in low) for each pwm cycle [0,1]

diff --git a/src/drivers/StepperDriver2PWM.cpp b/src/drivers/StepperDriver2PWM.cpp

index 7ca7cc31..09dd3e16 100644

--- a/src/drivers/StepperDriver2PWM.cpp

+++ b/src/drivers/StepperDriver2PWM.cpp

@@ -61,9 +61,6 @@ void StepperDriver2PWM::disable()

// init hardware pins

int StepperDriver2PWM::init() {

- // a bit of separation

- _delay(1000);

-

// PWM pins

pinMode(pwm1, OUTPUT);

pinMode(pwm2, OUTPUT);

diff --git a/src/drivers/StepperDriver4PWM.cpp b/src/drivers/StepperDriver4PWM.cpp

index d3678f00..f752ea6e 100644

--- a/src/drivers/StepperDriver4PWM.cpp

+++ b/src/drivers/StepperDriver4PWM.cpp

@@ -39,8 +39,6 @@ void StepperDriver4PWM::disable()

// init hardware pins

int StepperDriver4PWM::init() {

- // a bit of separation

- _delay(1000);

// PWM pins

pinMode(pwm1A, OUTPUT);

diff --git a/src/drivers/hardware_specific/esp32_mcu.cpp b/src/drivers/hardware_specific/esp32_mcu.cpp

index 7350316d..0bc2d863 100644

--- a/src/drivers/hardware_specific/esp32_mcu.cpp

+++ b/src/drivers/hardware_specific/esp32_mcu.cpp

@@ -20,6 +20,9 @@

#define _PWM_RES_MIN 1500

// max resolution

#define _PWM_RES_MAX 3000

+// pwm frequency

+#define _PWM_FREQUENCY 25000 // default

+#define _PWM_FREQUENCY_MAX 50000 // mqx

// structure containing motor slot configuration

// this library supports up to 4 motors

@@ -102,9 +105,10 @@ void _configureTimerFrequency(long pwm_frequency, mcpwm_dev_t* mcpwm_num, mcpwm

mcpwm_config_t pwm_config;

pwm_config.counter_mode = MCPWM_UP_DOWN_COUNTER; // Up-down counter (triangle wave)

pwm_config.duty_mode = MCPWM_DUTY_MODE_0; // Active HIGH

+ pwm_config.frequency = 2*pwm_frequency; // set the desired freq - just a placeholder for now https://github.com/simplefoc/Arduino-FOC/issues/76

mcpwm_init(mcpwm_unit, MCPWM_TIMER_0, &pwm_config); //Configure PWM0A & PWM0B with above settings

- mcpwm_init(mcpwm_unit, MCPWM_TIMER_1, &pwm_config); //Configure PWM0A & PWM0B with above settings

- mcpwm_init(mcpwm_unit, MCPWM_TIMER_2, &pwm_config); //Configure PWM0A & PWM0B with above settings

+ mcpwm_init(mcpwm_unit, MCPWM_TIMER_1, &pwm_config); //Configure PWM1A & PWM1B with above settings

+ mcpwm_init(mcpwm_unit, MCPWM_TIMER_2, &pwm_config); //Configure PWM2A & PWM2B with above settings

if (_isset(dead_zone)){

// dead zone is configured

@@ -149,15 +153,18 @@ void _configureTimerFrequency(long pwm_frequency, mcpwm_dev_t* mcpwm_num, mcpwm

mcpwm_num->timer[1].period.upmethod = 0;

mcpwm_num->timer[2].period.upmethod = 0;

_delay(1);

+ // _delay(1);

//restart the timers

mcpwm_start(mcpwm_unit, MCPWM_TIMER_0);

mcpwm_start(mcpwm_unit, MCPWM_TIMER_1);

mcpwm_start(mcpwm_unit, MCPWM_TIMER_2);

_delay(1);

-

- mcpwm_sync_enable(mcpwm_unit, MCPWM_TIMER_0, MCPWM_SELECT_SYNC_INT0, 0);

- mcpwm_sync_enable(mcpwm_unit, MCPWM_TIMER_1, MCPWM_SELECT_SYNC_INT0, 0);

- mcpwm_sync_enable(mcpwm_unit, MCPWM_TIMER_2, MCPWM_SELECT_SYNC_INT0, 0);

+ // Cast here because MCPWM_SELECT_SYNC_INT0 (1) is not defined

+ // in the default Espressif MCPWM headers. The correct const may be used

+ // when https://github.com/espressif/esp-idf/issues/5429 is resolved.

+ mcpwm_sync_enable(mcpwm_unit, MCPWM_TIMER_0, (mcpwm_sync_signal_t)1, 0);

+ mcpwm_sync_enable(mcpwm_unit, MCPWM_TIMER_1, (mcpwm_sync_signal_t)1, 0);

+ mcpwm_sync_enable(mcpwm_unit, MCPWM_TIMER_2, (mcpwm_sync_signal_t)1, 0);

_delay(1);

mcpwm_num->timer[0].sync.out_sel = 1;

_delay(1);

@@ -169,9 +176,8 @@ void _configureTimerFrequency(long pwm_frequency, mcpwm_dev_t* mcpwm_num, mcpwm

// - hardware speciffic

// supports Arudino/ATmega328, STM32 and ESP32

void _configure2PWM(long pwm_frequency,const int pinA, const int pinB) {

-

- if(!pwm_frequency || !_isset(pwm_frequency) ) pwm_frequency = 20000; // default frequency 20khz - centered pwm has twice lower frequency

- else pwm_frequency = _constrain(pwm_frequency, 0, 40000); // constrain to 40kHz max - centered pwm has twice lower frequency

+ if(!pwm_frequency || !_isset(pwm_frequency) ) pwm_frequency = _PWM_FREQUENCY; // default frequency 25hz

+ else pwm_frequency = _constrain(pwm_frequency, 0, _PWM_FREQUENCY_MAX); // constrain to 40kHz max

stepper_2pwm_motor_slots_t m_slot = {};

@@ -215,9 +221,8 @@ void _configure2PWM(long pwm_frequency,const int pinA, const int pinB) {

// - hardware speciffic

// supports Arudino/ATmega328, STM32 and ESP32

void _configure3PWM(long pwm_frequency,const int pinA, const int pinB, const int pinC) {

-

- if(!pwm_frequency || !_isset(pwm_frequency) ) pwm_frequency = 20000; // default frequency 20khz - centered pwm has twice lower frequency

- else pwm_frequency = _constrain(pwm_frequency, 0, 40000); // constrain to 40kHz max - centered pwm has twice lower frequency

+ if(!pwm_frequency || !_isset(pwm_frequency) ) pwm_frequency = _PWM_FREQUENCY; // default frequency 25hz

+ else pwm_frequency = _constrain(pwm_frequency, 0, _PWM_FREQUENCY_MAX); // constrain to 40kHz max

bldc_3pwm_motor_slots_t m_slot = {};

@@ -260,9 +265,8 @@ void _configure3PWM(long pwm_frequency,const int pinA, const int pinB, const int

// - Stepper motor - 4PWM setting

// - hardware speciffic

void _configure4PWM(long pwm_frequency,const int pinA, const int pinB, const int pinC, const int pinD) {

-

- if(!pwm_frequency || !_isset(pwm_frequency) ) pwm_frequency = 20000; // default frequency 20khz - centered pwm has twice lower frequency

- else pwm_frequency = _constrain(pwm_frequency, 0, 40000); // constrain to 50kHz max - centered pwm has twice lower frequency

+ if(!pwm_frequency || !_isset(pwm_frequency) ) pwm_frequency = _PWM_FREQUENCY; // default frequency 25hz

+ else pwm_frequency = _constrain(pwm_frequency, 0, _PWM_FREQUENCY_MAX); // constrain to 40kHz max

stepper_4pwm_motor_slots_t m_slot = {};

// determine which motor are we connecting

// and set the appropriate configuration parameters

@@ -365,7 +369,7 @@ void _writeDutyCycle4PWM(float dc_1a, float dc_1b, float dc_2a, float dc_2b, in

int _configure6PWM(long pwm_frequency, float dead_zone, const int pinA_h, const int pinA_l, const int pinB_h, const int pinB_l, const int pinC_h, const int pinC_l){

if(!pwm_frequency || !_isset(pwm_frequency) ) pwm_frequency = 20000; // default frequency 20khz - centered pwm has twice lower frequency

- else pwm_frequency = _constrain(pwm_frequency, 0, 40000); // constrain to 40kHz max - centered pwm has twice lower frequency

+ else pwm_frequency = _constrain(pwm_frequency, 0, _PWM_FREQUENCY_MAX); // constrain to 40kHz max - centered pwm has twice lower frequency

bldc_6pwm_motor_slots_t m_slot = {};

// determine which motor are we connecting

// and set the appropriate configuration parameters

@@ -428,4 +432,4 @@ void _writeDutyCycle6PWM(float dc_a, float dc_b, float dc_c, float dead_zone, i

}

}

}

-#endif

\ No newline at end of file

+#endif

diff --git a/src/drivers/hardware_specific/generic_mcu.cpp b/src/drivers/hardware_specific/generic_mcu.cpp

index 73aa3c9f..4a2360d9 100644

--- a/src/drivers/hardware_specific/generic_mcu.cpp

+++ b/src/drivers/hardware_specific/generic_mcu.cpp

@@ -12,7 +12,13 @@

#elif defined(_STM32_DEF_) // or stm32

-#elif defined(_SAMD21_) // samd21 for the moment, samd51 in progress...

+#elif defined(_SAMD21_) // samd21

+

+#elif defined(_SAMD51_) // samd51

+

+#elif defined(__SAME51J19A__) || defined(__ATSAME51J19A__) // samd51

+

+#elif defined(TARGET_RP2040)

#else

diff --git a/src/drivers/hardware_specific/rp2040_mcu.cpp b/src/drivers/hardware_specific/rp2040_mcu.cpp

new file mode 100644

index 00000000..097b7a6d

--- /dev/null

+++ b/src/drivers/hardware_specific/rp2040_mcu.cpp

@@ -0,0 +1,163 @@

+

+/**

+ * Support for the RP2040 MCU, as found on the Raspberry Pi Pico.

+ */

+#if defined(TARGET_RP2040)

+

+#define SIMPLEFOC_DEBUG_RP2040

+

+

+#ifdef SIMPLEFOC_DEBUG_RP2040

+

+#ifndef SIMPLEFOC_RP2040_DEBUG_SERIAL

+#define SIMPLEFOC_RP2040_DEBUG_SERIAL Serial

+#endif

+

+#endif

+

+#include "Arduino.h"

+

+

+

+

+// until I can figure out if this can be quickly read from some register, keep it here.

+// it also serves as a marker for what slices are already used.

+uint16_t wrapvalues[NUM_PWM_SLICES];

+

+

+// TODO add checks which channels are already used...

+

+void setupPWM(int pin, long pwm_frequency, bool invert = false) {

+ gpio_set_function(pin, GPIO_FUNC_PWM);

+ uint slice = pwm_gpio_to_slice_num(pin);

+ uint chan = pwm_gpio_to_channel(pin);

+ pwm_set_clkdiv_int_frac(slice, 1, 0); // fastest pwm we can get

+ pwm_set_phase_correct(slice, true);

+ uint16_t wrapvalue = ((125L * 1000L * 1000L) / pwm_frequency) / 2L - 1L;

+ if (wrapvalue < 999) wrapvalue = 999; // 66kHz, resolution 1000

+ if (wrapvalue > 3299) wrapvalue = 3299; // 20kHz, resolution 3300

+#ifdef SIMPLEFOC_DEBUG_RP2040

+ SIMPLEFOC_RP2040_DEBUG_SERIAL.print("Configuring pin ");

+ SIMPLEFOC_RP2040_DEBUG_SERIAL.print(pin);

+ SIMPLEFOC_RP2040_DEBUG_SERIAL.print(" slice ");

+ SIMPLEFOC_RP2040_DEBUG_SERIAL.print(slice);

+ SIMPLEFOC_RP2040_DEBUG_SERIAL.print(" channel ");

+ SIMPLEFOC_RP2040_DEBUG_SERIAL.print(chan);

+ SIMPLEFOC_RP2040_DEBUG_SERIAL.print(" frequency ");

+ SIMPLEFOC_RP2040_DEBUG_SERIAL.print(pwm_frequency);

+ SIMPLEFOC_RP2040_DEBUG_SERIAL.print(" top value ");

+ SIMPLEFOC_RP2040_DEBUG_SERIAL.println(wrapvalue);

+#endif

+ pwm_set_wrap(slice, wrapvalue);

+ wrapvalues[slice] = wrapvalue;

+ if (invert) {

+ if (chan==0)

+ hw_write_masked(&pwm_hw->slice[slice].csr, 0x1 << PWM_CH0_CSR_A_INV_LSB, PWM_CH0_CSR_A_INV_BITS);

+ else

+ hw_write_masked(&pwm_hw->slice[slice].csr, 0x1 << PWM_CH0_CSR_B_INV_LSB, PWM_CH0_CSR_B_INV_BITS);

+ }

+ pwm_set_chan_level(slice, chan, 0); // switch off initially

+}

+

+

+void syncSlices() {

+ for (int i=0;i1.0) ret = 1.0;

+ return ret;

+}

+

+void _writeDutyCycle6PWM(float dc_a, float dc_b, float dc_c, float dead_zone, int pinA_h, int pinA_l, int pinB_h, int pinB_l, int pinC_h, int pinC_l) {

+ writeDutyCycle(dc_a, pinA_h);

+ writeDutyCycle(swDti(dc_a, dead_zone), pinA_l);

+ writeDutyCycle(dc_b, pinB_h);

+ writeDutyCycle(swDti(dc_b,dead_zone), pinB_l);

+ writeDutyCycle(dc_c, pinC_h);

+ writeDutyCycle(swDti(dc_c,dead_zone), pinC_l);

+}

+

+#endif

diff --git a/src/drivers/hardware_specific/samd21_mcu.cpp b/src/drivers/hardware_specific/samd21_mcu.cpp

index cdbd82f8..cf8db836 100644

--- a/src/drivers/hardware_specific/samd21_mcu.cpp

+++ b/src/drivers/hardware_specific/samd21_mcu.cpp

@@ -1,69 +1,142 @@

-#if defined(ARDUINO_ARCH_SAMD)

-//#if defined(_SAMD21_)

+#include "./samd_mcu.h"

-#include "../hardware_api.h"

-#include "wiring_private.h"

-#include "./samd21_wo_associations.h"

+#ifdef _SAMD21_

-#define SIMPLEFOC_SAMD_DEBUG

-

-

-#ifndef SIMPLEFOC_SAMD_ALLOW_DIFFERENT_TCCS

-#define SIMPLEFOC_SAMD_ALLOW_DIFFERENT_TCCS false

+#ifndef TCC3_CH0

+#define TCC3_CH0 NOT_ON_TIMER

#endif

-

-#ifndef SIMPLEFOC_SAMD_PWM_RESOLUTION

-#define SIMPLEFOC_SAMD_PWM_RESOLUTION 1000

-#define SIMPLEFOC_SAMD_PWM_TC_RESOLUTION 250

+#ifndef TCC3_CH1

+#define TCC3_CH1 NOT_ON_TIMER

#endif

-

-#ifndef SIMPLEFOC_SAMD_MAX_TCC_PINCONFIGURATIONS

-#define SIMPLEFOC_SAMD_MAX_TCC_PINCONFIGURATIONS 12

+#ifndef TCC3_CH2

+#define TCC3_CH2 NOT_ON_TIMER

+#endif

+#ifndef TCC3_CH3

+#define TCC3_CH3 NOT_ON_TIMER

+#endif

+#ifndef TCC3_CH4

+#define TCC3_CH4 NOT_ON_TIMER

+#endif

+#ifndef TCC3_CH5

+#define TCC3_CH5 NOT_ON_TIMER

+#endif

+#ifndef TCC3_CH6

+#define TCC3_CH6 NOT_ON_TIMER

+#endif

+#ifndef TCC3_CH7

+#define TCC3_CH7 NOT_ON_TIMER

+#endif

+#ifndef TC6_CH0

+#define TC6_CH0 NOT_ON_TIMER

+#endif

+#ifndef TC6_CH1

+#define TC6_CH1 NOT_ON_TIMER

+#endif

+#ifndef TC7_CH0

+#define TC7_CH0 NOT_ON_TIMER

+#endif

+#ifndef TC7_CH1

+#define TC7_CH1 NOT_ON_TIMER

#endif

-// Wait for synchronization of registers between the clock domains

-static __inline__ void syncTCC(Tcc* TCCx) __attribute__((always_inline, unused));

-static void syncTCC(Tcc* TCCx) {

- while (TCCx->SYNCBUSY.reg & TCC_SYNCBUSY_MASK);

-}

+#define NUM_WO_ASSOCIATIONS 48

+

+/*

+ * For SAM D21 A/B/C/D Variant Devices and SAM DA1 A/B Variant Devices

+ * Good for SAMD2xE, SAMD2xG and SAMD2xJ devices. Other SAMD21s currently not supported in arduino anyway?

+ *

+ * Note: only the pins which have timers associated are listed in this table.

+ * You can use the values from g_APinDescription.ulPort and g_APinDescription.ulPin to find the correct row in the table.

+ *

+ * See Microchip Technology datasheet DS40001882F-page 30

+ */

+struct wo_association WO_associations[] = {

+

+ { PORTA, 0, TCC2_CH0, 0, NOT_ON_TIMER, 0},

+ { PORTA, 1, TCC2_CH1, 1, NOT_ON_TIMER, 0},

+ { PORTA, 2, NOT_ON_TIMER, 0, TCC3_CH0, 0},

+ { PORTA, 3, NOT_ON_TIMER, 0, TCC3_CH1, 1},

+ // PB04, PB05, PB06, PB07 - no timers

+ { PORTB, 8, TC4_CH0, 0, TCC3_CH6, 6},

+ { PORTB, 9, TC4_CH1, 1, TCC3_CH7, 7},

+ { PORTA, 4, TCC0_CH0, 0, TCC3_CH2, 2},

+ { PORTA, 5, TCC0_CH1, 1, TCC3_CH3, 3},

+ { PORTA, 6, TCC1_CH0, 0, TCC3_CH4, 4},

+ { PORTA, 7, TCC1_CH1, 1, TCC3_CH5, 5},

+ { PORTA, 8, TCC0_CH0, 0, TCC1_CH2, 2},

+ { PORTA, 9, TCC0_CH1, 1, TCC1_CH3, 3},

+ { PORTA, 10, TCC1_CH0, 0, TCC0_CH2, 2},

+ { PORTA, 11, TCC1_CH1, 1, TCC0_CH3, 3},

+ { PORTB, 10, TC5_CH0, 0, TCC0_CH4, 4},

+ { PORTB, 11, TC5_CH1, 1, TCC0_CH5, 5},

+ { PORTB, 12, TC4_CH0, 0, TCC0_CH6, 6},

+ { PORTB, 13, TC4_CH1, 1, TCC0_CH7, 7},

+ { PORTB, 14, TC5_CH0, 0, NOT_ON_TIMER, 0},

+ { PORTB, 15, TC5_CH1, 1, NOT_ON_TIMER, 0},

+ { PORTA, 12, TCC2_CH0, 0, TCC0_CH6, 6},

+ { PORTA, 13, TCC2_CH1, 1, TCC0_CH7, 7},

+ { PORTA, 14, TC3_CH0, 0, TCC0_CH4, 4},

+ { PORTA, 15, TC3_CH1, 1, TCC0_CH5, 5},

+ { PORTA, 16, TCC2_CH0, 0, TCC0_CH6, 6},

+ { PORTA, 17, TCC2_CH1, 1, TCC0_CH7, 7},

+ { PORTA, 18, TC3_CH0, 0, TCC0_CH2, 2},

+ { PORTA, 19, TC3_CH1, 1, TCC0_CH3, 3},

+ { PORTB, 16, TC6_CH0, 0, TCC0_CH4, 4},

+ { PORTB, 17, TC6_CH1, 1, TCC0_CH5, 5},

+ { PORTA, 20, TC7_CH0, 0, TCC0_CH6, 6},

+ { PORTA, 21, TC7_CH1, 1, TCC0_CH7, 7},

+ { PORTA, 22, TC4_CH0, 0, TCC0_CH4, 4},

+ { PORTA, 23, TC4_CH1, 1, TCC0_CH5, 5},

+ { PORTA, 24, TC5_CH0, 0, TCC1_CH2, 2},

+ { PORTA, 25, TC5_CH1, 1, TCC1_CH3, 3},

+ { PORTB, 22, TC7_CH0, 0, TCC3_CH0, 0},

+ { PORTB, 23, TC7_CH1, 1, TCC3_CH1, 1},

+ { PORTA, 27, NOT_ON_TIMER, 0, TCC3_CH6, 6},

+ { PORTA, 28, NOT_ON_TIMER, 0, TCC3_CH7, 7},

+ { PORTA, 30, TCC1_CH0, 0, TCC3_CH4, 4},

+ { PORTA, 31, TCC1_CH1, 1, TCC3_CH5, 5},

+ { PORTB, 30, TCC0_CH0, 0, TCC1_CH2, 2},

+ { PORTB, 31, TCC0_CH1, 1, TCC1_CH3, 3},

+ { PORTB, 0, TC7_CH0, 0, NOT_ON_TIMER, 0},

+ { PORTB, 1, TC7_CH1, 1, NOT_ON_TIMER, 0},

+ { PORTB, 2, TC6_CH0, 0, TCC3_CH2, 2},

+ { PORTB, 3, TC6_CH1, 1, TCC3_CH3, 3}

+};

+wo_association ASSOCIATION_NOT_FOUND = { NOT_A_PORT, 0, NOT_ON_TIMER, 0, NOT_ON_TIMER, 0};

-struct tccConfiguration {

- uint8_t pin;

- uint8_t alternate; // 1=true, 0=false

- uint8_t wo;

- union tccChanInfo {

- struct {

- int8_t chan;

- int8_t tccn;

- };

- uint16_t chaninfo;

- } tcc;

+struct wo_association& getWOAssociation(EPortType port, uint32_t pin) {

+ for (int i=0;i>pin_position)&0x01)==0x1?PIO_TIMER_ALT:PIO_TIMER;

+}

-/**

- * Global state

- */

-tccConfiguration tccPinConfigurations[SIMPLEFOC_SAMD_MAX_TCC_PINCONFIGURATIONS];

-uint8_t numTccPinConfigurations = 0;

-bool SAMDClockConfigured = false;

-bool tccConfigured[TCC_INST_NUM+TC_INST_NUM];

+

+void syncTCC(Tcc* TCCx) {

+ while (TCCx->SYNCBUSY.reg & TCC_SYNCBUSY_MASK); // Wait for synchronization of registers between the clock domains

+}

+

+

/**

* Configure Clock 4 - we want all simplefoc PWMs to use the same clock. This ensures that

@@ -71,6 +144,10 @@ bool tccConfigured[TCC_INST_NUM+TC_INST_NUM];

* clocks.

*/

void configureSAMDClock() {

+

+ // TODO investigate using the FDPLL96M clock to get 96MHz timer clocks... this

+ // would enable 48KHz PWM clocks, and setting the frequency between 24Khz with resolution 2000, to 48KHz with resolution 1000

+

if (!SAMDClockConfigured) {

SAMDClockConfigured = true; // mark clock as configured

for (int i=0;i>1) {

- case 0:

- GCLK_CLKCTRL_ID_ofthistcc = GCLK_CLKCTRL_ID(GCM_TCC0_TCC1);//GCLK_CLKCTRL_ID_TCC0_TCC1;

- break;

- case 1:

- GCLK_CLKCTRL_ID_ofthistcc = GCLK_CLKCTRL_ID(GCM_TCC2_TC3);//GCLK_CLKCTRL_ID_TCC2_TC3;

- break;

- case 2:

- GCLK_CLKCTRL_ID_ofthistcc = GCLK_CLKCTRL_ID(GCM_TC4_TC5);//GCLK_CLKCTRL_ID_TC4_TC5;

- break;

- case 3:

- GCLK_CLKCTRL_ID_ofthistcc = GCLK_CLKCTRL_ID(GCM_TC6_TC7);

- break;

- default:

- return;

+ case 0: GCLK_CLKCTRL_ID_ofthistcc = GCLK_CLKCTRL_ID(GCM_TCC0_TCC1); break; //GCLK_CLKCTRL_ID_TCC0_TCC1;

+ case 1: GCLK_CLKCTRL_ID_ofthistcc = GCLK_CLKCTRL_ID(GCM_TCC2_TC3); break; //GCLK_CLKCTRL_ID_TCC2_TC3;

+ case 2: GCLK_CLKCTRL_ID_ofthistcc = GCLK_CLKCTRL_ID(GCM_TC4_TC5); break; //GCLK_CLKCTRL_ID_TC4_TC5;

+ case 3: GCLK_CLKCTRL_ID_ofthistcc = GCLK_CLKCTRL_ID(GCM_TC6_TC7); break;

+ default: return;

}

// Feed GCLK4 to TCC

REG_GCLK_CLKCTRL = (uint16_t) GCLK_CLKCTRL_CLKEN | // Enable GCLK4

GCLK_CLKCTRL_GEN_GCLK4 | // Select GCLK4

GCLK_CLKCTRL_ID_ofthistcc; // Feed GCLK4 to tcc

- while (GCLK->STATUS.bit.SYNCBUSY); // Wait for synchronization

+ while (GCLK->STATUS.bit.SYNCBUSY); // Wait for synchronization

tccConfigured[tccConfig.tcc.tccn] = true;

if (tccConfig.tcc.tccn>=TCC_INST_NUM) {

Tc* tc = (Tc*)GetTC(tccConfig.tcc.chaninfo);

-

// disable

tc->COUNT8.CTRLA.bit.ENABLE = 0;

while ( tc->COUNT8.STATUS.bit.SYNCBUSY == 1 );

@@ -149,7 +216,6 @@ void configureTCC(tccConfiguration& tccConfig, long pwm_frequency, bool negate=f

// enable

tc->COUNT8.CTRLA.bit.ENABLE = 1;

while ( tc->COUNT8.STATUS.bit.SYNCBUSY == 1 );

-

#ifdef SIMPLEFOC_SAMD_DEBUG

Serial.print("Initialized TC ");

Serial.println(tccConfig.tcc.tccn);

@@ -184,10 +250,6 @@ void configureTCC(tccConfiguration& tccConfig, long pwm_frequency, bool negate=f

while ( (tcc->SYNCBUSY.reg & chanbit) > 0 );

}

- // enable double buffering

- //tcc->CTRLBCLR.bit.LUPD = 1;

- //while ( tcc->SYNCBUSY.bit.CTRLB == 1 );

-

// Enable TC

tcc->CTRLA.reg |= TCC_CTRLA_ENABLE | TCC_CTRLA_PRESCALER_DIV1; //48Mhz/1=48Mhz/2(up/down)=24MHz/1024=24KHz

while ( tcc->SYNCBUSY.bit.ENABLE == 1 ); // wait for sync

@@ -243,254 +305,27 @@ void configureTCC(tccConfiguration& tccConfig, long pwm_frequency, bool negate=f

-/**

- * Attach the TCC to the pin

- */

-bool attachTCC(tccConfiguration& tccConfig) {

- if (numTccPinConfigurations>=SIMPLEFOC_SAMD_MAX_TCC_PINCONFIGURATIONS)

- return false;

- pinMode(tccConfig.pin, OUTPUT);

- pinPeripheral(tccConfig.pin, (tccConfig.alternate==1)?EPioType::PIO_TIMER_ALT:EPioType::PIO_TIMER);

- tccPinConfigurations[numTccPinConfigurations++] = tccConfig;

- return true;

-}

-

-

-

-

-

-

-/**

- * Check if the configuration is in use already.

- */

-bool inUse(tccConfiguration& tccConfig) {

- for (int i=0;i=TCC_INST_NUM)

- return false;

-

- if (pinAh.tcc.chan==pinBh.tcc.chan || pinAh.tcc.chan==pinBl.tcc.chan || pinAh.tcc.chan==pinCh.tcc.chan || pinAh.tcc.chan==pinCl.tcc.chan)

- return false;

- if (pinBh.tcc.chan==pinCh.tcc.chan || pinBh.tcc.chan==pinCl.tcc.chan)

- return false;

- if (pinAl.tcc.chan==pinBh.tcc.chan || pinAl.tcc.chan==pinBl.tcc.chan || pinAl.tcc.chan==pinCh.tcc.chan || pinAl.tcc.chan==pinCl.tcc.chan)

- return false;

- if (pinBl.tcc.chan==pinCh.tcc.chan || pinBl.tcc.chan==pinCl.tcc.chan)

- return false;

-

- if (pinAh.tcc.chan!=pinAl.tcc.chan || pinBh.tcc.chan!=pinBl.tcc.chan || pinCh.tcc.chan!=pinCl.tcc.chan)

- return false;

- if (pinAh.wo==pinAl.wo || pinBh.wo==pinBl.wo || pinCh.wo!=pinCl.wo)

- return false;

-

- return true;

-}

-

-

-

-

-bool checkPeripheralPermutationCompatible(tccConfiguration pins[], uint8_t num) {

- for (int i=0;i=TCC_INST_NUM || pinAl.tcc.tccn>=TCC_INST_NUM || pinBh.tcc.tccn>=TCC_INST_NUM

- || pinBl.tcc.tccn>=TCC_INST_NUM || pinCh.tcc.tccn>=TCC_INST_NUM || pinCl.tcc.tccn>=TCC_INST_NUM)

- return false;

-

- // check we're not in use

- if (inUse(pinAh) || inUse(pinAl) || inUse(pinBh) || inUse(pinBl) || inUse(pinCh) || inUse(pinCl))

- return false;

-

- // check pins are all different tccs/channels

- if (pinAh.tcc.chaninfo==pinBh.tcc.chaninfo || pinAh.tcc.chaninfo==pinBl.tcc.chaninfo || pinAh.tcc.chaninfo==pinCh.tcc.chaninfo || pinAh.tcc.chaninfo==pinCl.tcc.chaninfo)

- return false;

- if (pinAl.tcc.chaninfo==pinBh.tcc.chaninfo || pinAl.tcc.chaninfo==pinBl.tcc.chaninfo || pinAl.tcc.chaninfo==pinCh.tcc.chaninfo || pinAl.tcc.chaninfo==pinCl.tcc.chaninfo)

- return false;

- if (pinBh.tcc.chaninfo==pinCh.tcc.chaninfo || pinBh.tcc.chaninfo==pinCl.tcc.chaninfo)

- return false;

- if (pinBl.tcc.chaninfo==pinCh.tcc.chaninfo || pinBl.tcc.chaninfo==pinCl.tcc.chaninfo)

- return false;

-